Tool manufacturing plays a central role in the invenio portfolio: Short communication paths and a close coordination between the individual development and production steps enable us to optimally coordinate our in-house competencies. With special consideration of uniform wall thickness, analysis of the filling and flow behaviour (mould flow) as well as reasonable demoulding characteristics, we develop production-ready and binding CAx models. No matter whether for series, prototype or hybrid tools: All work steps are called up from our range of services and efficiently controlled by our project management.

We Process Common Injection Moulding Materials such as

High-temperature-resistant materials

PA, PP, ABS

TPE

A Wide Range of Possibilities

We have our own injection moulding machines with a clamping force of 20 to 400 tonnes at our disposal, as well as those of our cooperation partners. This means we can produce components with a weight between 1 and approx. 1,800 grams.

Thanks to our many years of experience, we can also offer you 2-component components, inserts, overmoulded components and thermoplastic foam casting (TFC).

Expertise Means High Quality

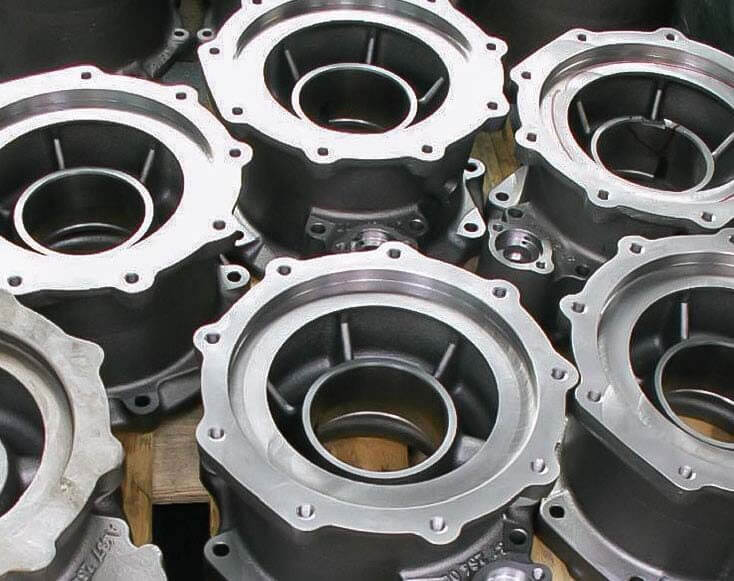

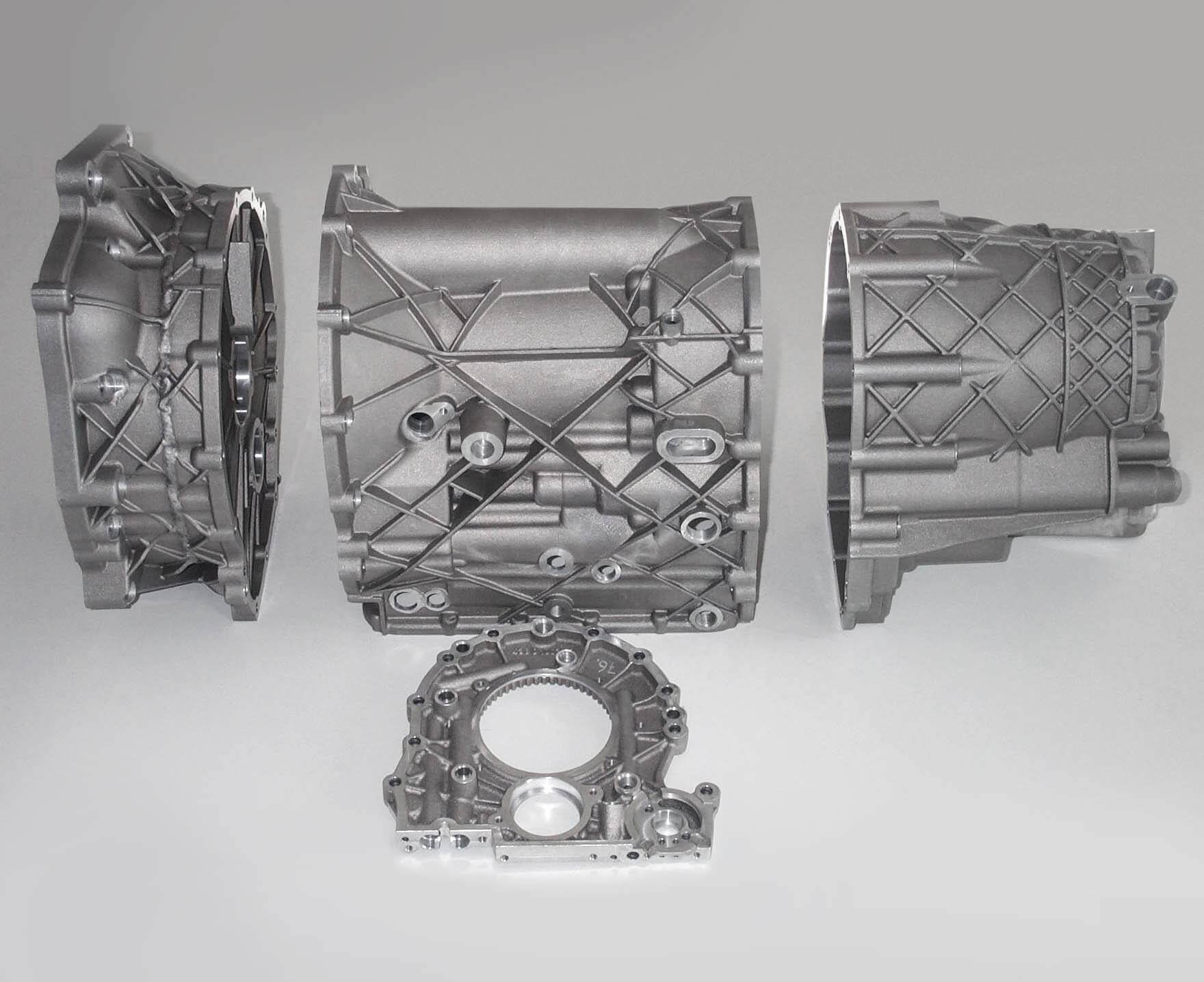

Based on our know-how in the fields of design, calculation and production, we develop your components with regard to strength, weight and cost-optimised design. We create the production-relevant CAD design for you and carry out all steps with regard to process management. We pay particular attention to aspects of mould separation, demoulding characteristics, core design and analysis using casting simulations.

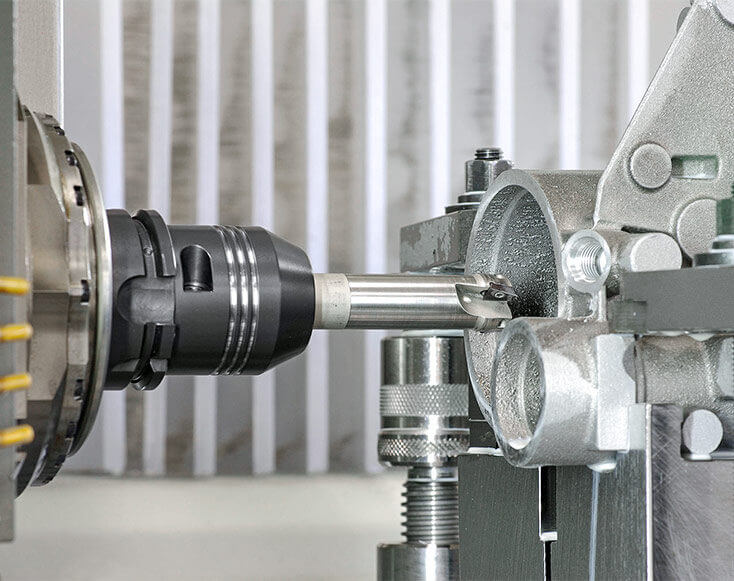

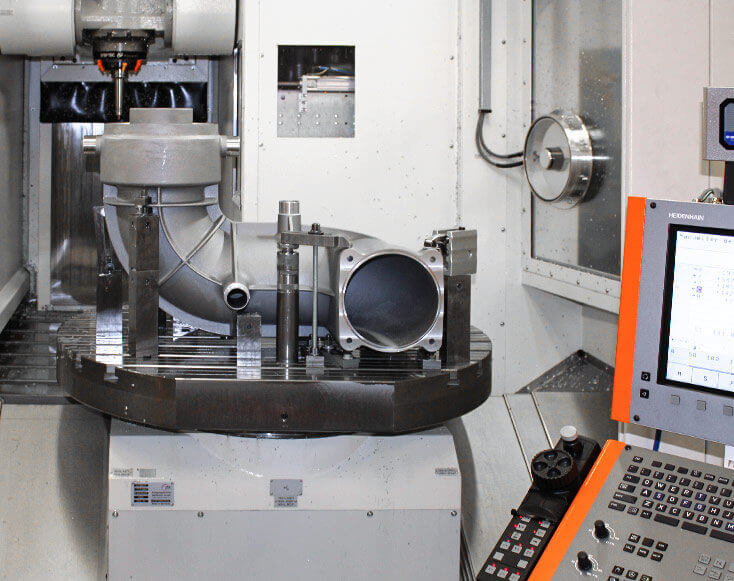

We Use Innovative and Proven Processes to Produce the Models from the CAx Data

-

CNC 3-/5-axis milling

-

Croning-Sand

-

High-Speed Cutting (HSC)

-

Polystyrene models

-

Selective laser sintering (SLS)

For the casting processes, we always select the appropriate solution for your castings from sand casting, investment casting or a differential pressure process.

Would You like to contact us?

Gladly we are at your disposal for any questions!