Entdecken Sie den entscheidenden Mehrwert in der geometrischen Absicherung

60.000 Bauteile, Millionen von potenziellen Engstellen: Die virtuelle geometrische Absicherung (VGA) von Triebwerken stellt Hersteller regelmäßig vor große Herausforderungen. Neben der Menge an Bauteilen wird die drei- bis fünfjährige Entwicklungszeit besonders durch die notwendigen Varianten immer komplexer und fehleranfälliger. Für einen Kunden aus der Luft- und Raumfahrt hat die invenio Virtual Technologies (VT) den Quality-Monitor mit Künstlicher Intelligenz erfolgreich in einer weiteren Branche etabliert.

Wie verhält sich die Performance der Algorithmen mit den speziellen Triebwerksgeometrien und der dichten Packung? Wie gut kann die KI mit den gefundenen Problemstellen umgehen? Das waren nur zwei Fragen, die sich die VT-Expert:innen und Berater:innen vorab gestellt haben. Die Antworten im Kundenprojekt haben schnell gezeigt: Quality-Monitor ist auch in der Triebwerksentwicklung die führende VGA-Lösung am Markt, die für vollständige Transparenz in den bereitgestellten 3D-Daten sorgt. Mit der Software-Lösung konnten auch bei Triebwerken bestehende, überwiegend manuelle Prüfprozesse erfolgreich automatisiert und die Effizienz in der Entwicklung dadurch deutlich gesteigert werden.

Intelligente Berechnungen reduzieren Anzahl kritischer Stellen

Bereits die ersten Testläufe an Produktivdaten verliefen vielversprechend: Quality-Monitor wertete die Nachbarschaftsbeziehungen für rund 60.000 Bauteile gemäß einem Regelwerk aus, erkannte mehr als 875.000 potenziell problematische Beziehungen und berechnete am Ende rund 250.000 konkrete Regelverletzungen. Für den vollständig automatisierten Prozess vom Import der Daten bis zur Information der Anwender:innen benötigte die VT-Lösung knapp acht Stunden. Im Laufe des Projekts konnten alle diese Werte durch die intelligenten Algorithmen und optimierte Regeln erfolgreich verbessert werden: Am Ende reduzierte sich der Aufwand mit der VT-Lösung auf 340.000 Paarungen und einige hundert bis wenige tausend Problemstellen. Die notwendige Berechnungszeit verringerte sich dadurch um rund 40 Prozent.

„Mit Quality-Monitor bieten wir seit Jahren das führende Werkzeug in der Geometrieprüfung an. Führend werden wir damit auch weiterhin bleiben, da wir unser Produkt konsequent weiterentwickeln. Trotzdem haben wir großen Respekt, wenn wir Quality-Monitor in einer neuen Branche etablieren. Ich bin stolz darauf, dass sich unsere Software auch bei so komplexen Gebilden wie Triebwerken schnell als die gewohnt zuverlässige und präzise Lösung erwiesen hat“, so Hermann Gaigl, Geschäftsführer der invenio VT. Für die Luft- und Raumfahrt gilt wie in allen anderen Branchen: Hersteller können mit Quality-Monitor geometrische Konflikte frühzeitig erkennen, das beschleunigt die Entwicklung und eliminiert zuverlässig alle Fehler.

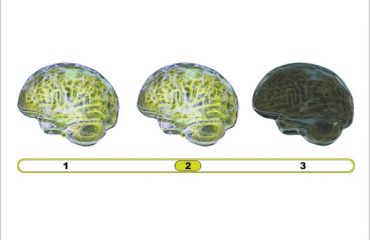

In unserem Fachartikel im Digital Engineering Magazin erfahren Sie neben weiteren Zahlen, Daten und Fakten außerdem, auf was sich die Anwender:innen beim KI-Einsatz mit Triebwerken fokussiert haben, wie bei Quality-Monitor zusätzlicher Mehrwert durch intelligente KI-Bilder entsteht und welche entscheidende Rolle die Vererbung im Gesamtprozess spielt.