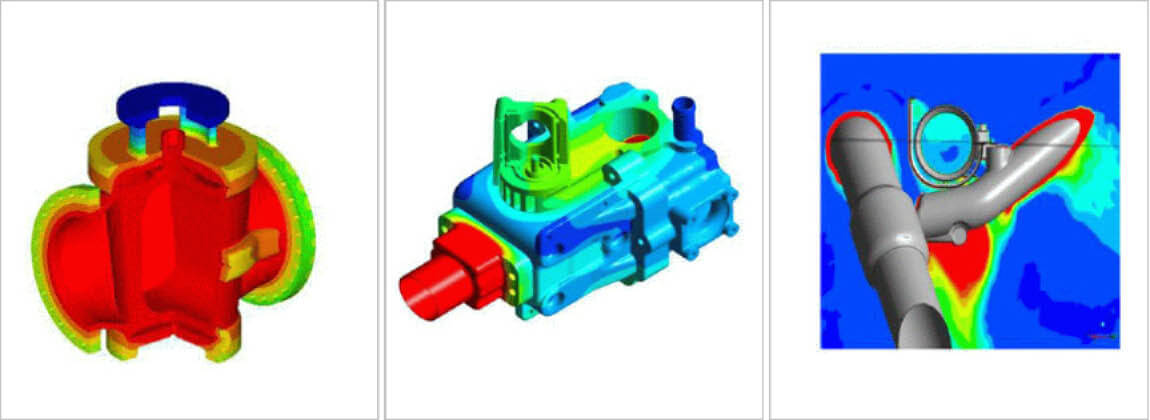

Use under complex temperature conditions places special demands on the products and designs. Thermal expansion or creep processes can lead to instability and, in extreme cases, failure. It is therefore essential to evaluate and optimise the service life of a component before it is manufactured, taking into account the complex thermo-mechanical loads. Thermal simulation is implemented in the early development process for this purpose.

Thermal simulation can be used to determine the temperature and heat transfer of sensitive components, such as in electronics, at all points of the product. It is the prerequisite for efficient heat management in high-performance components: Heat distribution or cooling concepts can be optimised on this basis as early as the design stage, for example to dissipate heat away from sensitive areas.

Thermal Simulation Protects Your Product

In the thermal simulation, the temperature can be calculated both stationary and transient – i.e. the temperature changes over time – in or around components. The associated thermal operating conditions are also shown in the simulation. A temperature rise can thus be calculated over time in order to accurately estimate the location of the maximum temperature peak at each observation time. Thermal simulation is also frequently used to reduce heat losses or to lower thermal conductivity.

Thermal simulations are one of our core calculation competences and have been carried out for more than 35 years for many customers from a wide range of industrial applications. Coupled with flow simulations (CFD), they provide reliable information in the areas of thermal management, cooling or heat balance.

Our Portfolio

- Consideration of thermomechanics

- Consideration of heat transport via convection, radiation and heat conduction

- Determination of the structural behaviour under consideration of the thermal expansion

- Coupling of temperature field and flow analyses

- Thermal flow analyses with chemical reactions

- Thermal shock analyses

- Development of cooling concepts

Would you like more details on how we can best support you with your product? Take a look at our flyer or contact us for an initial discussion.

Would You like to contact us?

Gladly we are at your disposal for any questions!

Or call us: +49 (2154) 8874-0