The flow of air, gases or liquids plays a major role in many constructions if they flow around or through them. The energy consumption of the products often depends directly on the flow losses, which is why the determination of pressure losses is a classic task of a flow analysis. Use Flow Simulation to increase the performance and functionality of your design with lower energy consumption.

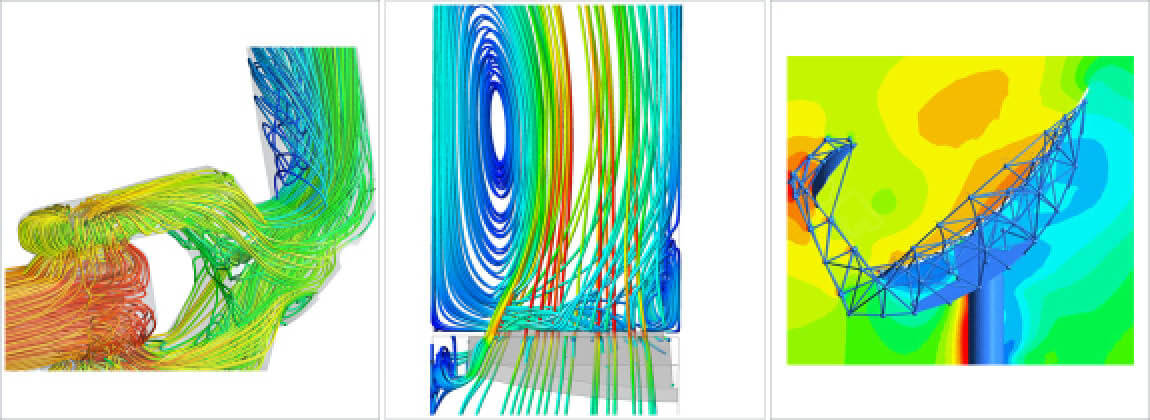

In contrast to expensive experimental tests and the analysis of individual measuring points, numerical CFD flow simulation provides a deeper insight into the physical processes and visualises the overall situation in the early development phase. Flows and flow patterns are simulated mathematically and the flow paths are visualised: resulting pressures, temperatures, flow forces, heat and particle flows are thus already visible in the development phase.

Our Flow Simulation Ensures Your Energy-Efficient Component

Pressure loss is caused by flow separation, also known as recirculation, and can lead to a complete stall. Common causes of a flow separation are, for example, sharp deflections or unsteady cross-sectional expansions in the construction or component elements that are located in the flow guide. These cause an obstruction to the flow and can result in unwanted noise as well as pressure loss.

Our experts compile the analysed velocity, pressure, density, concentration and temperature distributions in an analysis report and use the results of the flow simulation to derive specific measures to improve the design. Among other things, baffles can then be used, for example, whose position and geometry are defined by means of semi-manual optimisation.

Other FEM calculations can also be combined with the flow simulation, for example by carrying out a temperature calculation in parallel to simulate active air cooling. The mechanical load on the environment can also be determined and included in the FEM strength calculation.

Portfolio in Flow Simulation

- Determination of flow velocity and flow distribution

- Flow calculation with liquids, gases and fluid mixtures

- consideration of laminar and turbulent flow behaviour

- Interaction with the environment (Fluid Structure Interaction)

- Filling processes with free liquid surfaces including sloshing

- Calculation of wind loads on building components and structures

- Single and multi-phase flows - compressible and incompressible media

- Heat transfer between liquid, gaseous and solid constructions

- Evaluation of local thermal comfort, e.g. 'draught rating' DR

We are happy to support you in making your product energy-efficient through flow-optimised concepts. Would you like more details on how we can best support you with your product?

Take a look at our flyer or contact us for an initial discussion.

Would You like to contact us?

Gladly we are at your disposal for any questions!

Or call us: +49 (2154) 8874-0