Whether in mechanical and plant engineering, in the automotive industry or in medical technology – products should function without damage over their intended service life. However, instead of extensive tests on prototypes, component concepts can be tested well before production with the help of strength calculations. Your big advantage: the load-bearing capacity of a component is demonstrated quickly and cost-effectively at a very early stage in the development process and can be optimized in a targeted manner before the manufacturing process. With our support, you can rule out failure during the entire product service life with sufficient certainty – regardless of whether fractures, impermissible plastic or elastic deformations and instabilities such as buckling and buckling occur.

Our Strength Calculation Optimizes Your Product

- the structural integrity, fatigue strength and durability are examined and evaluated

- knowledge of product behavior under real conditions is simulated

- Material costs are minimized and product performance is increased at the same time

- Product development time and time-to-market are shortened

- The expensive production and testing of physical prototypes is reduced

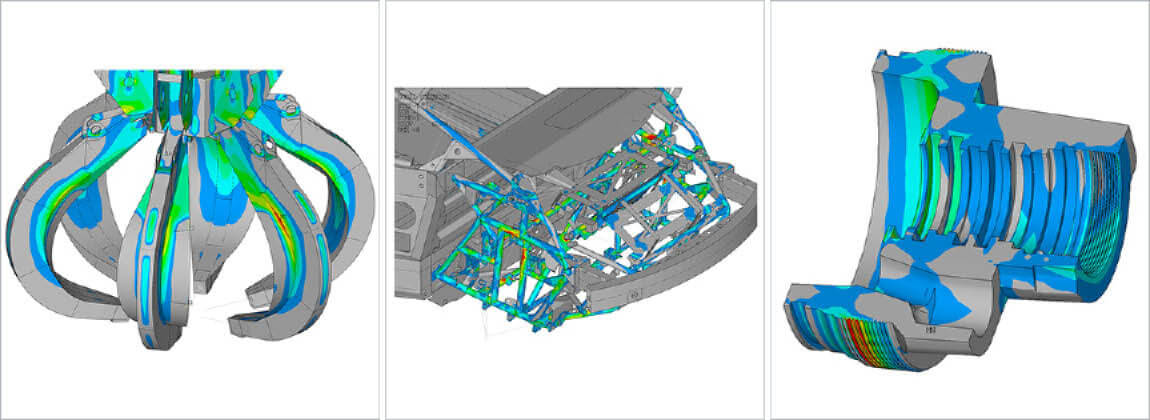

Our calculation follows several steps: First, the geometry of the structure to be calculated is meshed with finite elements. We always create these FE meshes semi-manually so that the element quality meets our accuracy requirements at all times. We work with you to define the boundary conditions and material properties, taking into account aspects such as the egg structure situation, possible interaction with the environment and the stiffness of the bearing in the calculation model.

Evaluation and Proof of Strength

This is followed by the evaluation of the stresses for the strength verification, in which the necessary safety factors and coefficients as well as application-specific evaluation methods are applied. The evaluation of the result requires not only theoretical know-how, but also our experience and extensive practical knowledge in order to correctly interpret the FEM analysis and arrive at the best solution for you.

The evaluation of fasteners such as rivets or weld seams is also carried out semi-automatically, as a superposition of individual stress components is often required here. The calculation engineers at invenio have developed an extensive macro library that enables a reliable strength analysis to be carried out quickly and efficiently.

Portfolio in the Strength Calculation

- Linear, non-linear as well as static and dynamic structural calculations

- Inspection of constructions during development

- Fatigue and service life analyses

- Shock and vibration analyses

- Damage analysis to find the cause

- Dynamic collision analysis in the automotive, railway and medical device sectors

- Consideration of inertia, damping and vibration behaviour

- Determination of the technical security and the utilisation rates

- Multi-body analyses (MBS) also as basis for strength calculations

- Transport, earthquake, explosion as well as overpressure and vacuum considerations

- Buckling and stability analyses

- Emergency stop considerations and 'misuse' load cases

Would you like more details on how we can best support you with your product? Take a look at our flyer or contact us for an initial discussion.

Would You like to contact us?

Gladly we are at your disposal for any questions!

Or call us: +49 (2154) 8874-0