Whether IT services in the field of FEM or process automation – our range of services for the development of customized FEM software covers the entire spectrum of FEM applications, industry-specific standards and regulations, and technical mechanics. In particular, in the areas of FEM analysis and the automation of recurring tasks, costs and resources can be significantly reduced through the use of customized FEM software.

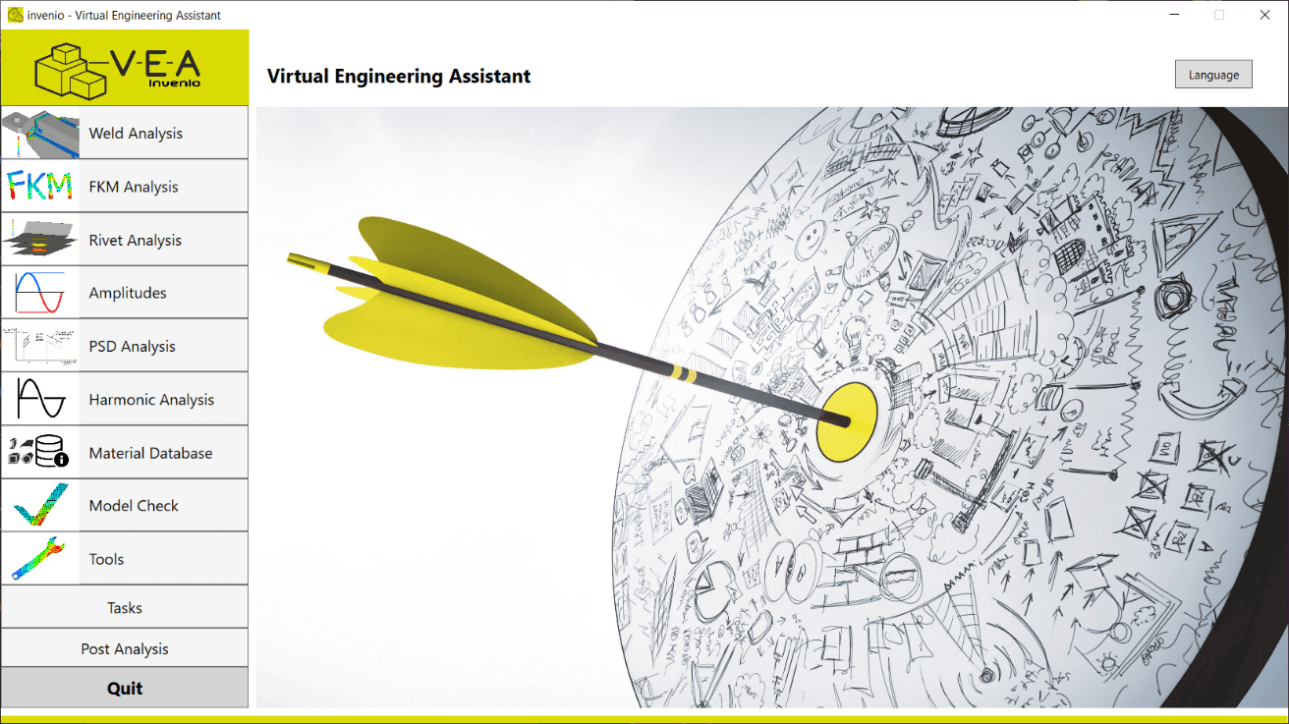

Based on our own requirements, we developed the FEM software collection Virtual Engineering Assistant (VEA) for performing standard- and guideline-compliant verification of weld seams, fasteners, and complex structures at our company.

The Virtual Engineering Assistant is a collection of software modules that can be used to check the strength of FEM structures in order to quickly and reliably identify component deficiencies or potential for optimization – but also for the pure optimization of work processes in terms of effectiveness and safety. The VEA covers the following standards and guidelines in particular:

- Eurocode 3

- DVS 1612

- DVS 1608

- FKM-Guideline

- and many more upon request

Your advantages in developing your customized FEM software in collaboration with us:

- Development of customized software based on scripting (Python) or .NET (C#) for Windows

- Modular software structure: possibilities for efficient adaptations and extensions

- Individual consulting based on many years of experience and expertise

- Over 30 years of experience in FEM calculation and evaluation according to industry-specific standards and guidelines

- Extensive expertise in technical and theoretical solid mechanics

Sample projects

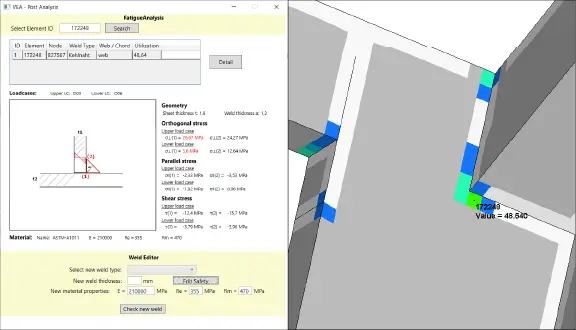

Weld seam analysis program

The weld seam analysis integrated in VEA reliably evaluates the stresses from the FEM calculation based on various standards and guidelines (e.g., according to DVS 1612 and DVS 1608), thus enabling a comprehensive representation of product performance. Since stress conversions to actual weld seam thicknesses and stress transformations are automated, the costs of modeling can be significantly reduced. Changes to seam shape and materials can be subsequently verified with little effort.

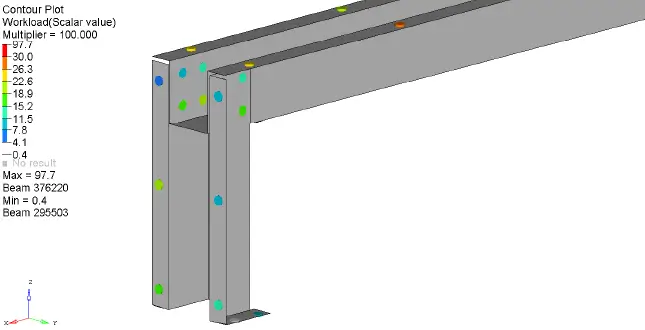

Custom software for analyzing fasteners

The visual representation of the performance of virtual prototypes following FEM calculation is an important step toward increasingly performing component evaluations digitally. In addition to identifying potential for optimization, custom FEM software offers the necessary process reliability to avoid errors in recurring tasks.

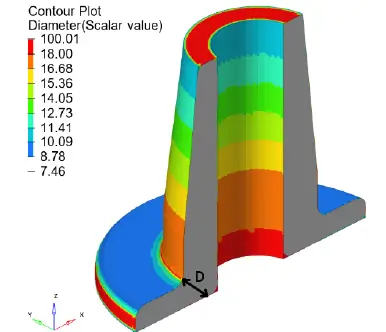

Component verification according to FKM guidelines

When it comes to automating processes, customized algorithms play a major role in relieving engineers of error-prone and time-consuming tasks. Based on the 'Virtual Engineering Assistant', individual modules can be developed specifically for our customers. The figure shows the automated calculation of local component thicknesses for stress verification according to FKM guidelines.

Our promise of quality:

Would You like to contact us?

Gladly we are at your disposal for any questions!

Or call us: +49 (2154) 8874-0