GENERAL INFORMATION

To read a PDF file you need the Adobe Acrobat Reader.

More information only available in German. Please refer to the German version for more information.

CUSTOMER SATISFACTION

Only satisfied customers are long-term customers. That is why your satisfaction is the benchmark for our success. And we only achieve success by taking your wishes into account and implementing them into ideal solutions in shortest time along the whole process – this happens seamlessly and without frictional losses. Therefore we require your support to stay close to our customers.

Under the e-mail address customerservice(at)invenio.net we established a virtual post-office box which you can use to give us your feedback during the project phase.

Please be sure to give us your project number so we can allocate your message.

CATEGORIES

VIDEO FOOTAGE

We are engineers, programmers, computer scientists, technicians and business people. We are customer understanders and industry experts. We are conceptionists and doers: We are invenio.

Automation at invenio

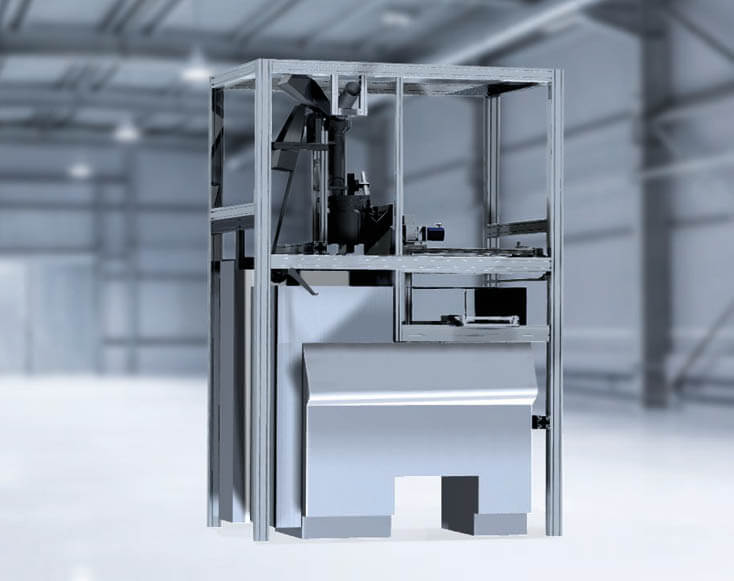

Automatic monolith-wrapping

GALLERY

Various automation projects in the overview.

Sensing of welding particles

Controlled quality to avoid complaints

Purpose of the System

Automatic detection of particles in the components of the exhaust system (for example medium and end mufflers) in series production

Use

Avoidance of complaints about undesired noises caused by particles inside

Particularities

Manual or robot-operated system, Sensing of particles by assessing sound spectra in a sound-isolated measurement room integrated with the system, Four systems in series operation

Endurance tests on domestic products

High cycle count and exact measurement results

Purpose of the System

Simulation of wear and tear by simulated use and automatic measuring data analysis

Use

Rapid and automatic simulated use via a high cycle count for pre-series testing respectively comprehensive testing of quality guarantee for series later on

Particularities

Easy-operated test construction, Measurement of torques respectively geometric wear values for quality assessment

Test bench for the control of exhaust components

Full-automatic function and sealing test

Purpose of the System

Function tests on exhaust components: System tightness, functioning of exhaust flap, mobility of threads

Use

Early fault detection leading to cost reduction by the quality assurance of the follow-up processes

Particularities

Testing of system variants, Sealing analysis by means of pressure-drop test, as well as full-automatic sealing of all connected openings, Testing of thread moveability by means of torque-monitored screw modules, Testing of electric actuator of flap control, power consumption, closing angle and closure time

Leak test installation

Analysis of leakage devices for medium-conducting components

Purpose of the System

Full-automatic test of oil-conducting components, for example, with regards to the tightness of oil sumps

Use

Testing of 100% tightness in series production – Product quality assurance and avoidance of faults in follow-up processes

Particularities

Automatic leakage analysis by pressure-drop test, Automatic part tensioning and sealing of all openings, for example on flanges, thread bores or the openings for integrated components such as oil pumps

COMPETENCE SPECTRA

For many years, our company has had solution competence for all phases of the engineering process.

The automation of machines and plants is one of invenio's core competences. The well-rehearsed invenio team develops fully and semi-automated systems across all industries – from theory to practical implementation and from design to practical handling.

WOULD YOU LIKE TO CONtACT US?

Gladly we are at your disposal for any questions!