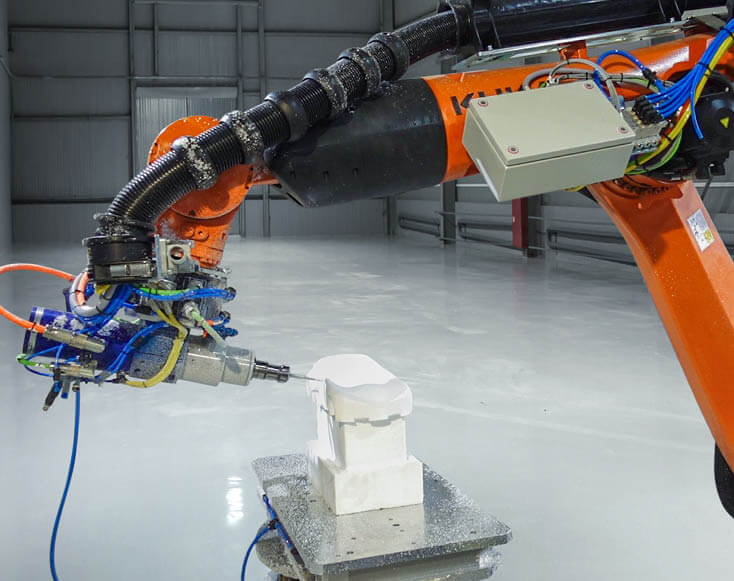

Robot-assisted automation, CAD/CAM systems and CNC-controlled manufacturing characterise the image of modern and cost-efficient production lines. This increasing use of robotics in industry enables significantly greater flexibility and more efficient options in the development of automation solutions. At the same time, however, new challenges arise in terms of complexity, both in the development phase and during the commissioning of these systems. These challenges are part of our speciality: invenio is your partner in the field of robotics – whether you need products for smart milling robots, plant automation or the implementation of industrial robots, we can provide you with everything from a single source.

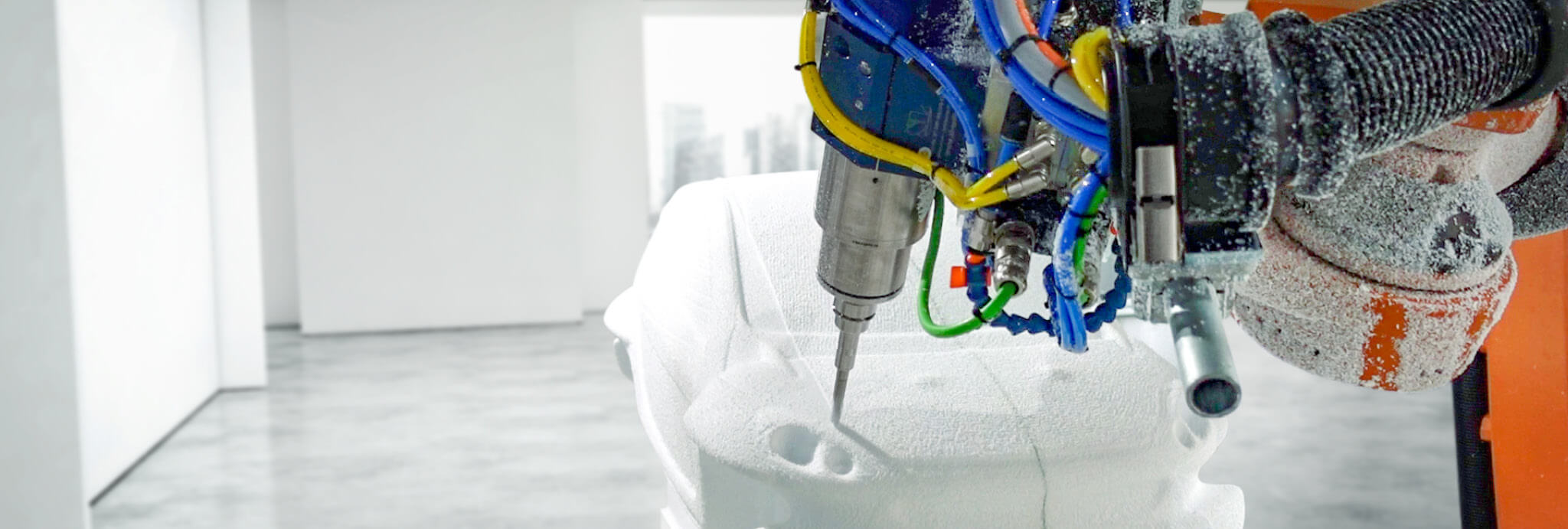

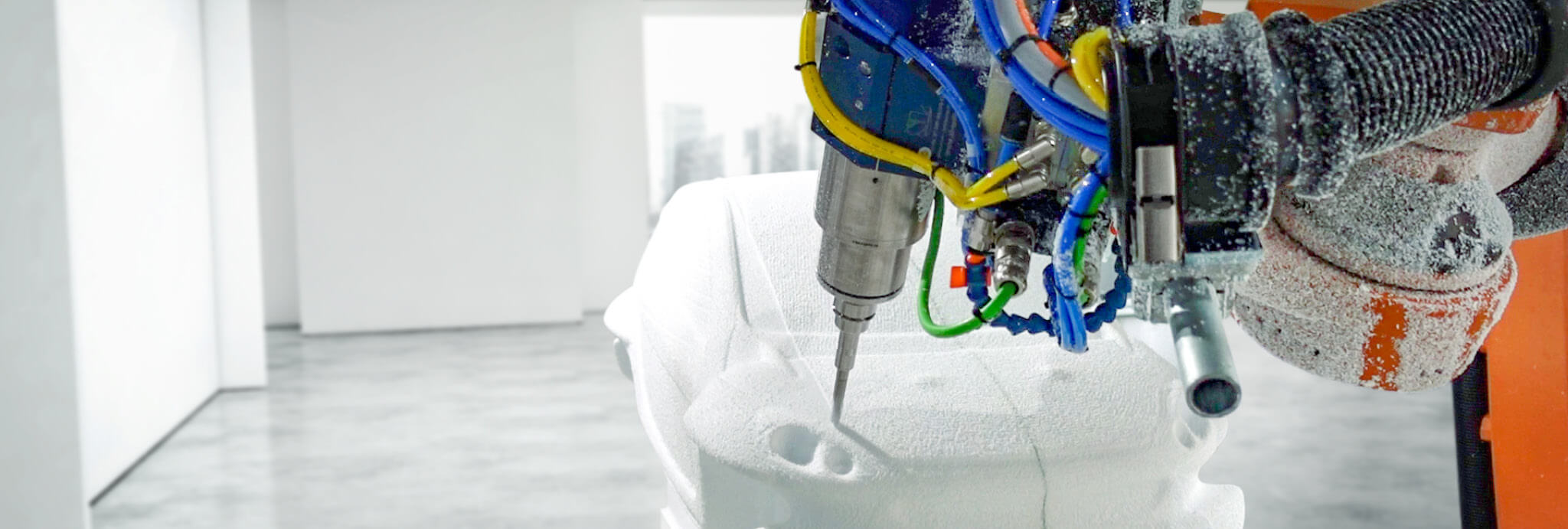

High-precision robot milling is one of our core competences. Our milling services are mainly focussed on the automotive industry. Typical areas of application are the production of individual parts, test samples, prototypes and small series.

Automotive: Milling for Interior and Exterior

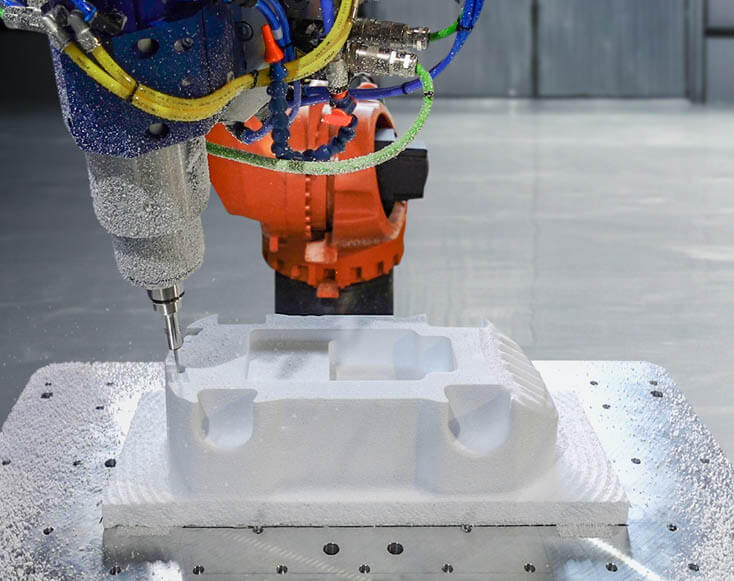

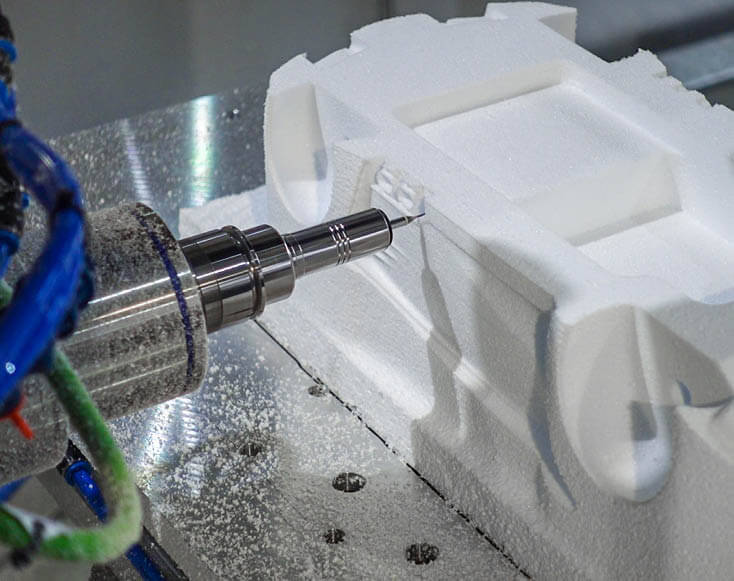

Technical vehicle components are often very complex – their detailed representation requires innovative solutions: our modern milling robots with six to eight axes enable a particularly high degree of digitalisation in the work process. Based on your CAD data, our robot cells mill test moulds that originate from bumpers. Interior and exterior components in particular often require openings and apertures that either cannot be produced using other methods – or where an injection moulding tool is not worthwhile due to the quantity, as is the case with special series or sports models. Whether on one level or in all positions and contours - up to eight axes of the robot offer impressive customisation options to suit your requirements.

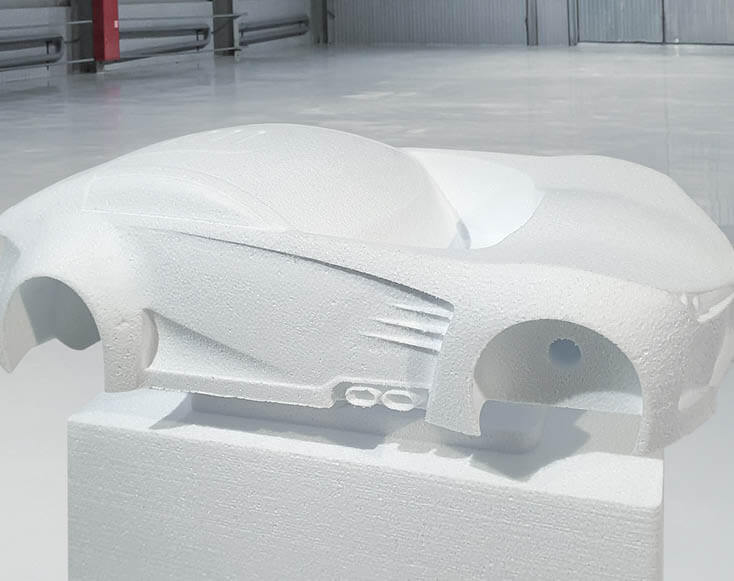

Model Making: Milling from the Polystyrene Block

We process numerous lightweight materials, such as polystyrene blocks and other technical moulded parts made of expanded polystyrene (EPS), plastic, foam or wood. Thanks to its low density, elasticity and durability, EPS is a popular material in many industries. We use it to create test and show models for you as well as components for assemblies from various industries as part of contract manufacturing. Our robot cells mill 3D geometries with very sophisticated free-form surfaces from the block material with a high level of detail. The fine-pored, millable polystyrene foam makes it possible to achieve an extremely attractive surface quality. As the robot codes are generated in advance in CAM software, all we need from you are the finished CAD models – saving you both time and money, regardless of whether you are a model maker, steel caster or scenery designer in a theatre: we produce everything – from seat and vehicle models to exhibit and display models and even entire scenery for decorations.

With our experienced invenio experts and many years of expertise, we stand for full service in the field of robotics. Versatile and flexible – we are your reliable partner from the initial consultation to the concrete technical solution proposal. Have your components and models manufactured by invenio: Our automation solutions promise shorter development times, lower costs and are characterised by high quality.

Would You like to contact us?

Gladly we are at your disposal for any questions!