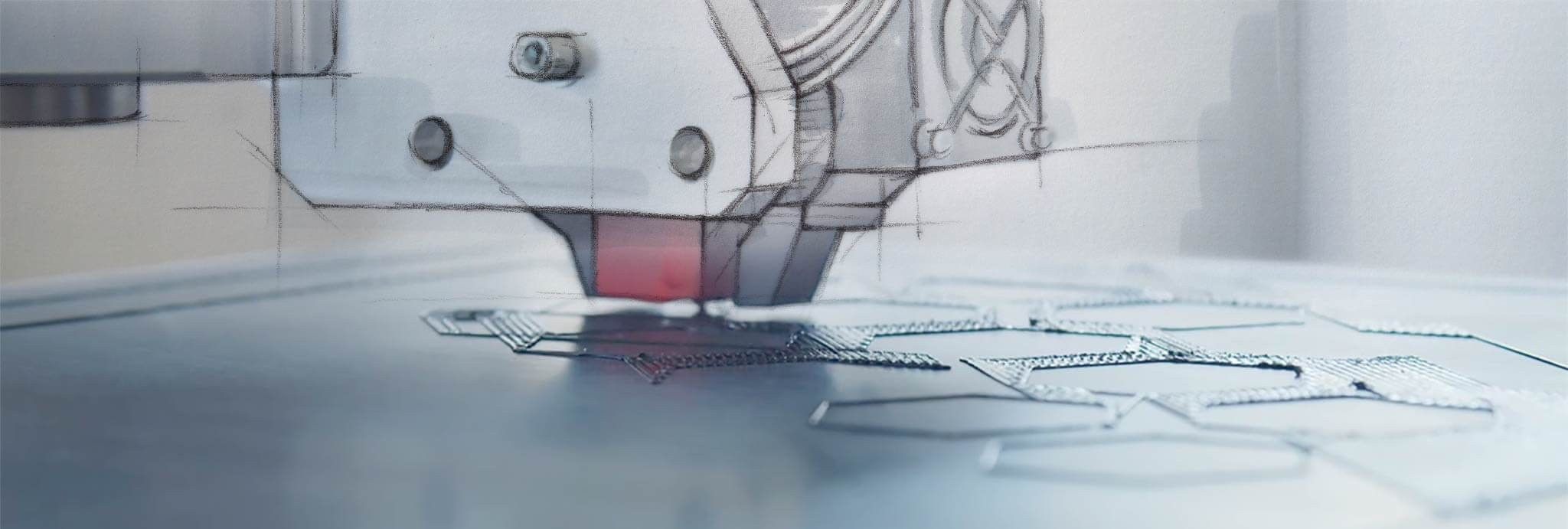

In an industrial environment, conventional 3D printing quickly reaches its limits – versatile industrial robots with special print heads are therefore increasingly being used to open up new economic potential in the manufacturing industry: The possible applications and efficiency are enormous, as the combination of additive and subtractive manufacturing can create a fully automated, hybrid manufacturing system. Years of experience in robot technology, in-depth expertise in the use of industrial robots and a comprehensive range of services in automation – this makes invenio your reliable partner for exceptional results when using industrial 3D printing processes.

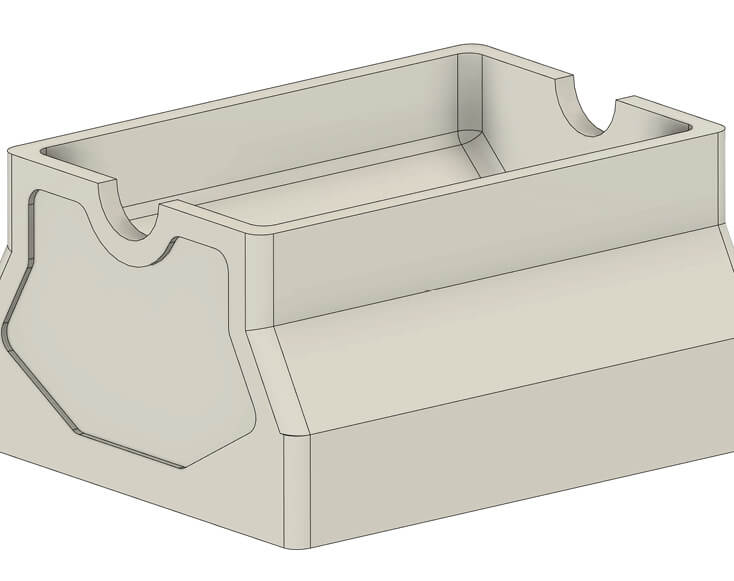

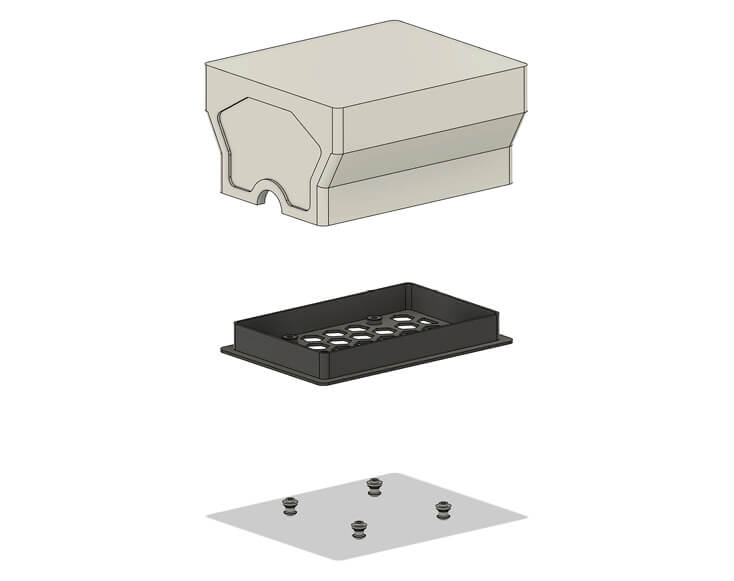

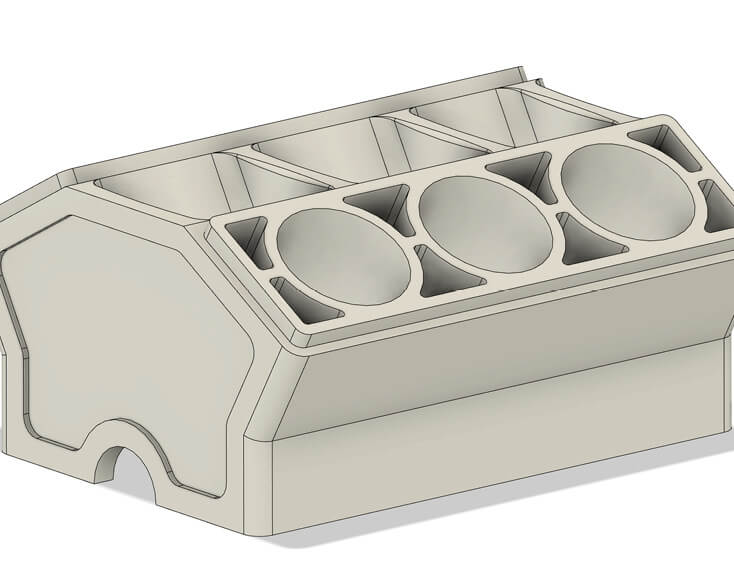

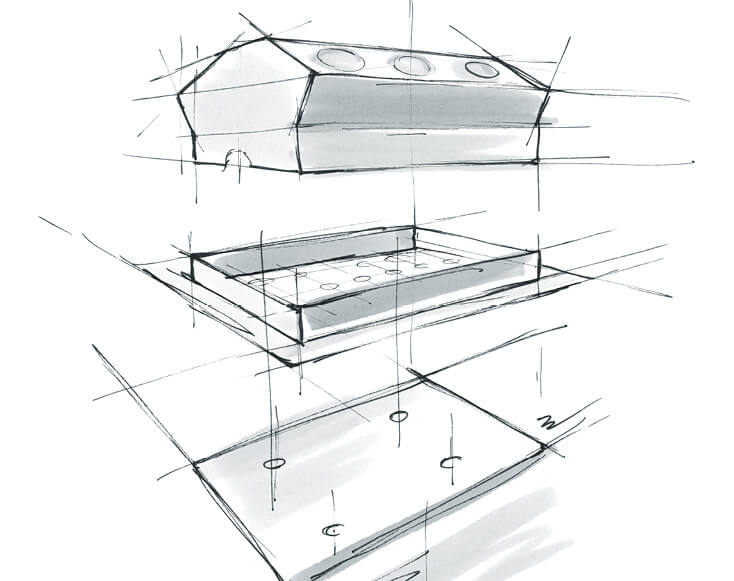

Conventional 3D printers build the desired objects layer by layer in 3-axis systems. This involves the use of extensive support structures, which are very time-consuming and therefore costly to remove once the component has been completed. Modern industrial robots, on the other hand, offer considerably more advantages here: With up to eight axes of the robot arm, spatial free-form structures are possible that require few or no support structures. In addition, the reach and the large working area mean that large free-form parts such as prototype moulds or hybrid components are possible.

This video was created in collaboration with Autodesk for the 'Autodesk Accelerate 2021' event.

Large-Format Objects – Stable, Light and Manufactured Automatically

Do you need a component that is stable, lightweight and, above all, large? Thanks to the enormous range of robot units, even metre-long and highly complex components can be produced cost-effectively and easily in one piece - with invenio's proven precision and speed. Parts printed on site and exactly as required also eliminate the need for long supply chains and logistical effort. We support you with a wide range of options for manufacturing customised components from a wide variety of materials.

Your Advantages with invenio

-

Additive manufacturing and industrial 3-D printing

-

Resource-saving manufacturing

-

Significant material savings in the production of exhibit and illustrative models

-

More cost-effective and time-efficient manufacturing

-

Complete solutions (robotic milling and 3-D printing) with only one robot (system)

More Power – Combination of Robotic Milling and 3-D Printing

Combining the technology of milling and 3D printing in a single robot system enables production of unlimited size, surface quality and precision in conjunction with maximum axial freedom. At invenio, both processes can be used alternately. For example, a negative model can be produced using 3D printing, merged with the blank previously milled from Exporit and then the entire model can be reworked in detail using robot milling technology. Such constructions can be vehicles, drive screws, sanitary objects or even stage and backdrop models.

You can obtain the individual model from invenio – including all data preparation - or the complete robot system for your own production. We look forward to hearing from you.

Would You like to contact us?

Gladly we are at your disposal for any questions!