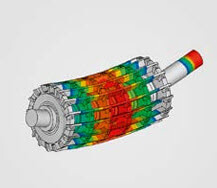

Realistic simulations using modern calculation methods – such as FEM (Finite Element Method) and CFD (Computational Fluid Dynamics) analyses – reveal product properties so that these can be taken into account early on in the design phase. Thanks to the FEM calculations, reliability is increased and both potential and weak points in the design are uncovered. This demonstrably reduces development times and costs – because expensive and time-consuming prototypes for testing are a thing of the past.

Well-known customers benefit from our 30 years of experience with FEM calculations in order to better predict and evaluate the structural behaviour of their components in terms of mechanics, thermals or flow and to optimize the design accordingly.

We Support your Product Development with these FEM Calculations

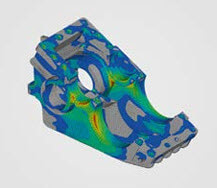

Strength Calculation

A strength analysis provides a precise statement about how your design will behave in terms of mechanical stresses and strength. In this way, potential problems with stress concentrations, deformation or expansion become clear at an early stage of development.

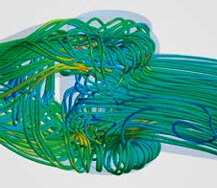

Flow Simulation

In addition to critical pressure losses or flow distributions, the flow analyses also provide information about the temperature distribution in the structures. By optimising the geometry on the basis of a CFD flow analysis, the formation of vortices or heat flow can be improved.

Thermal Simulation

In order to design an effective cooling or heating system, a thermal analysis is essential. Unwanted expansions can lead to instability. In the thermal simulation, both stationary and transient temperature fields, thermal gradients and the heat flow are analysed.

Dynamic Analyses

Many structures are subjected to dynamic loads, e.g. crashes. Inertia and plasticisation play a major role here. Using specialised software, we simulate the behaviour of your products accurately and reliably, thereby ensuring efficient vehicle safety, among other things.

Vibration Measurement

Ensure the operational and fatigue strength of the design. Dynamic analyses, from modal analysis to response spectrum analyses in the time and frequency range, are essential to rule out mechanical failure due to resonance effects.

Safety and Quality for your Rail Vehicles

FEM calculation has become indispensable as a cost-effective and efficient tool within the product development process. With its origins in the aerospace industry and subsequently in the automotive sector, today it is also essential for ensuring safety in rail vehicle technology. Thanks to our experience and extensive knowledge of standards and regulations, we offer all FEM calculations in the field of rail vehicle technology – from freight wagons and equipment to slewing gears and rolling stock.

In all our services, we focus on our customers – whether a holistic development project in close invenio-wide co-operation or just an individual service is required. Benefit from our FEM calculation and optimise the design of your product at an early stage in order to achieve the highest quality and safety in compliance with all standards and regulations.

Would You like to contact us?

Gladly we are at your disposal for any questions!

Or call us: +49 (2154) 8874-0