In today's industrial world, geometry inspection plays a crucial role across all sectors. It is an indispensable part of digital product development, especially in the development of digital prototypes. The geometry check ensures that all components fit together correctly and that no collisions or distance violations occur. This is crucial in order to guarantee the functionality and safety of the products.

The challenges and requirements for geometry testing can be diverse. Development cycles of four to seven years are not uncommon in many industries. In times of digitalisation, volatile markets and dynamic technological leaps, many manufacturers are facing major challenges: The acceleration of development processes offers an immense competitive advantage, as customers nowadays expect real substance, sustainable and durable products as well as top quality. Virtual geometric validation has established itself as a key technology here; geometric consistency and the monitoring of virtual products are fundamental to overall progress from the first drafts to the finished product.

Geometric Protection: Background and Development

Geometric validation is a process that has evolved over many years to meet the growing demands of product development. Originally, geometric checks were carried out manually, which was both time-consuming and error-prone. The inspection was like looking for a needle in a pile. With increasing digitalisation and the introduction of modern CAD systems and powerful calculation hardware, many of these processes could be automated, which significantly increased accuracy and efficiency. However, these systems have also reached their limits, especially when handling large amounts of data and identifying subtle geometric problems. This is where geometric inspection with Quality-Monitor comes in to close these gaps and provide a comprehensive solution.

The Importance of Digitalisation and AI in Modern Product Development

Digitalisation has revolutionised product development. Virtual prototypes and the digital twin enable engineers to test and optimise designs before physical prototypes are built. This not only saves time and costs, but also enables design errors to be identified and rectified at an early stage.

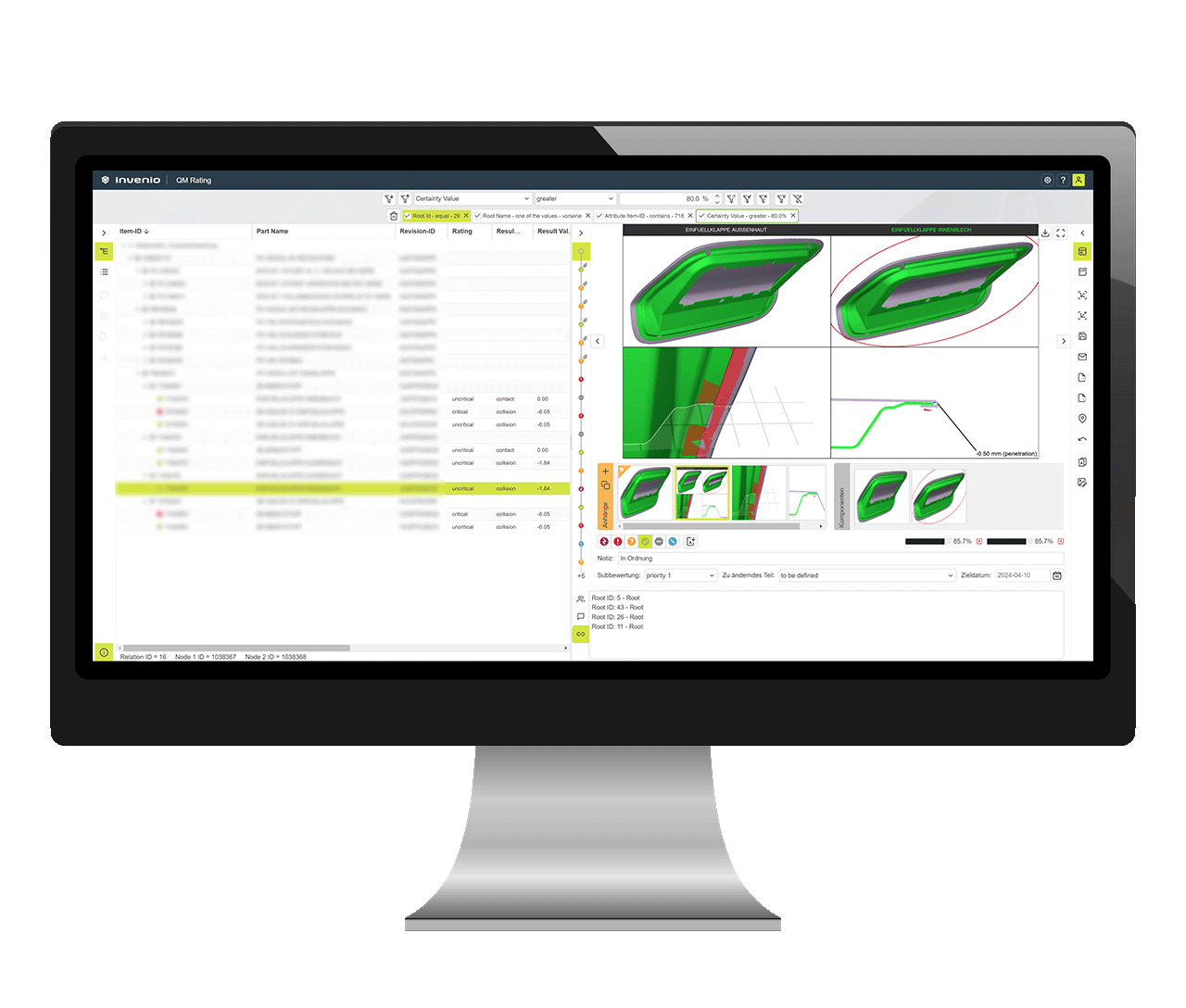

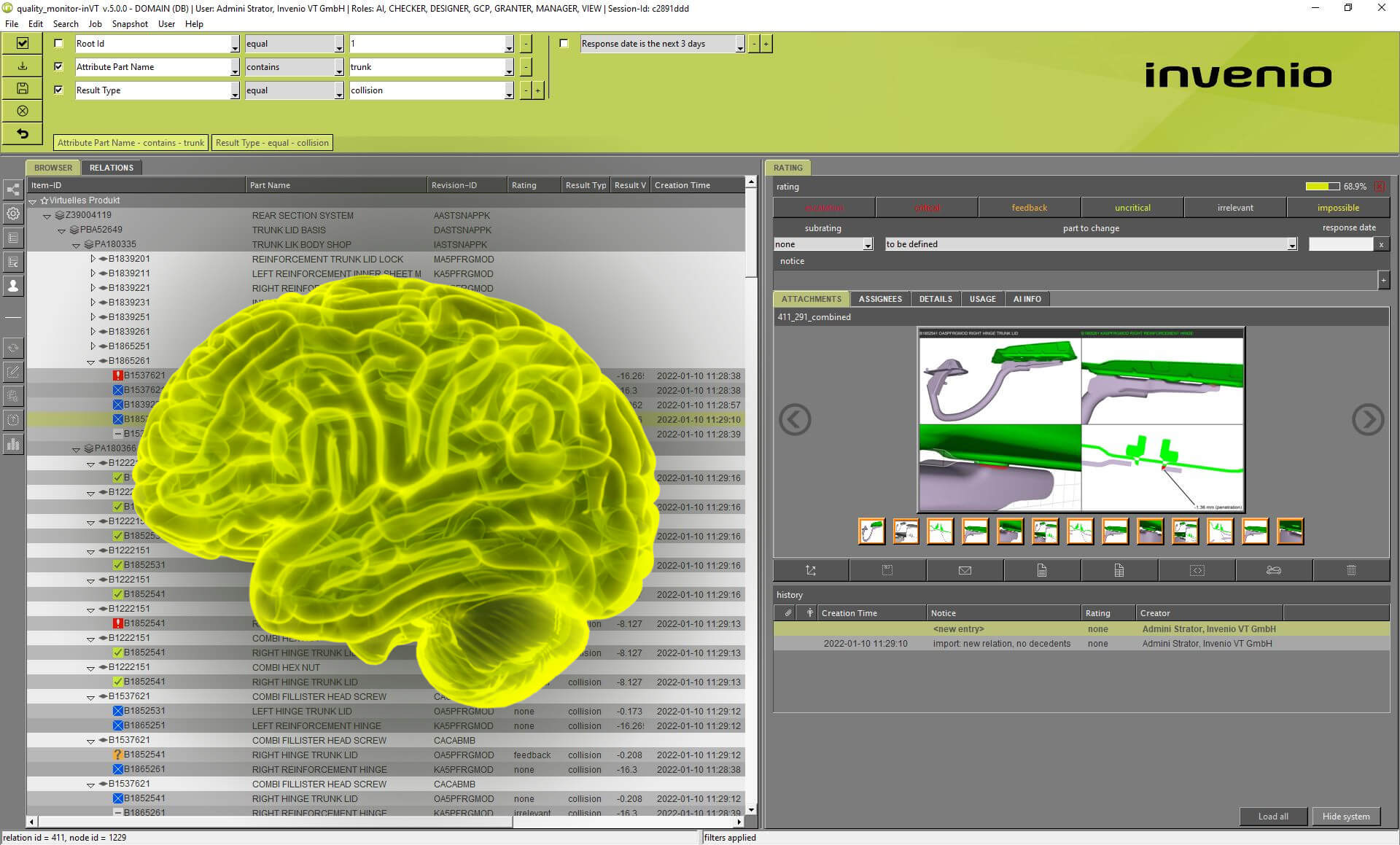

With Quality-Monitor and its further development Quality-Monitor Web, invenio Virtual Technologies (VT) offers the leading solution for virtual geometric validation in order to calculate, evaluate, communicate and track collisions and distance violations in digital products or digital twins. By integrating artificial intelligence, users can find all geometric problems in their digital product more efficiently. This feature is unique to Quality-Monitor and Quality-Monitor Web and provides decisive added value. With the help of invenio AI, the process of virtual geometric validation can be made up to 80% more efficient.

With the Intelligent Software Solution You Get:

- Efficient process of virtual geometric validation

- High-performance calculation of huge amounts of data

- Intelligent handling of the results (inheritance, delta method and much more)

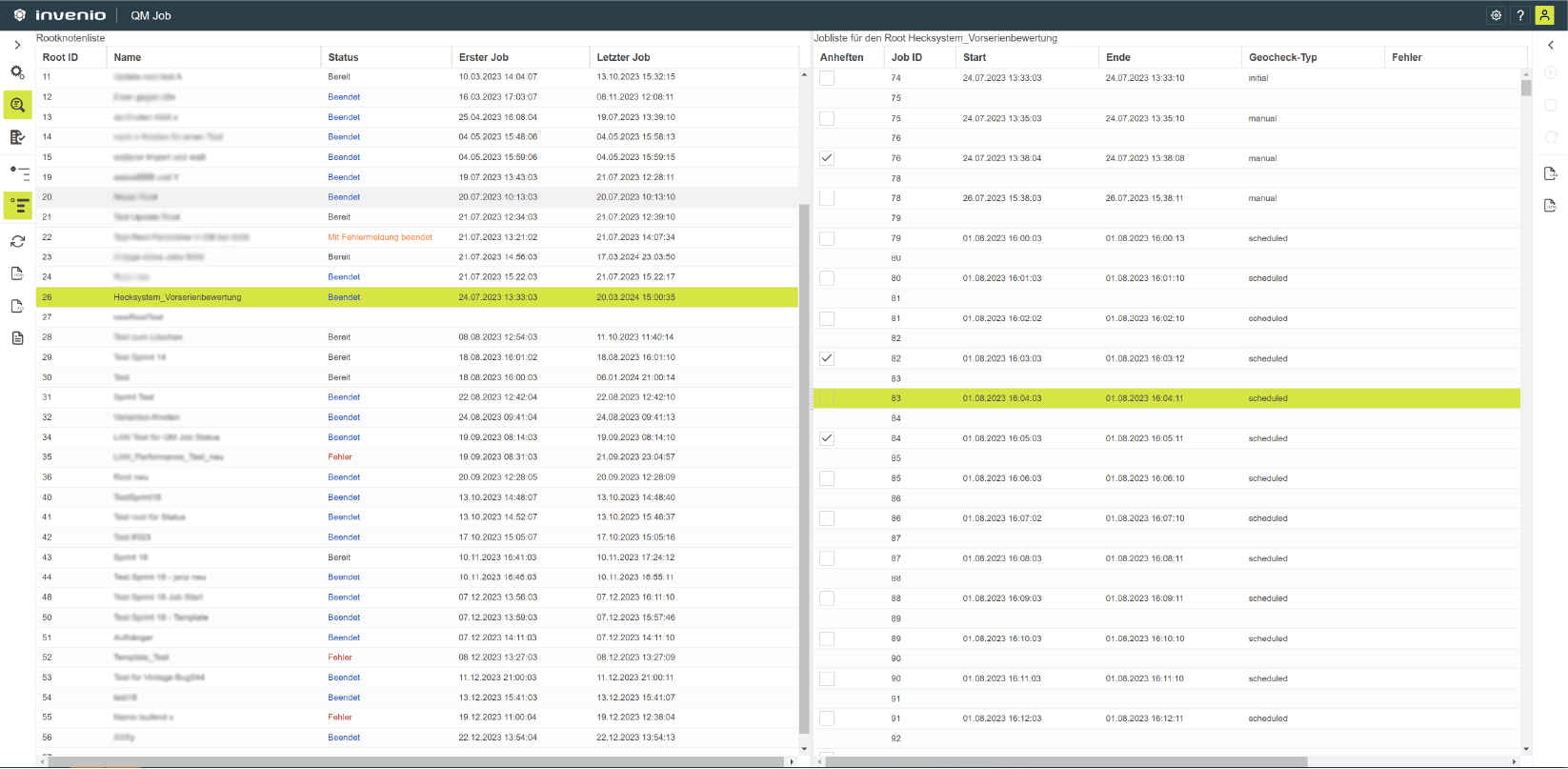

- Daily updated overview of all conflict points in the digital prototypes

- User-optimized evaluation at the touch of a button

- Effortless communication and tracking

- History of each issue from initial assessment to release

- Reports and statistics

The integrated and unique artificial intelligence supports you in the evaluation and interpretation of the calculation results. Lengthy evaluations are a thing of the past. If you use our AI and Quality-Monitor, the process of virtual geometric validation becomes up to 80% more efficient.

Quality-Monitor has been used for years by SMEs and well-known OEMs across all industries in digital product development to safeguard development data.

A Look Inside

Your Technological Advantages – Unique and Tried and Tested

Intelligent Algorithms

With Quality-Monitor Web you get a high-performance solution:

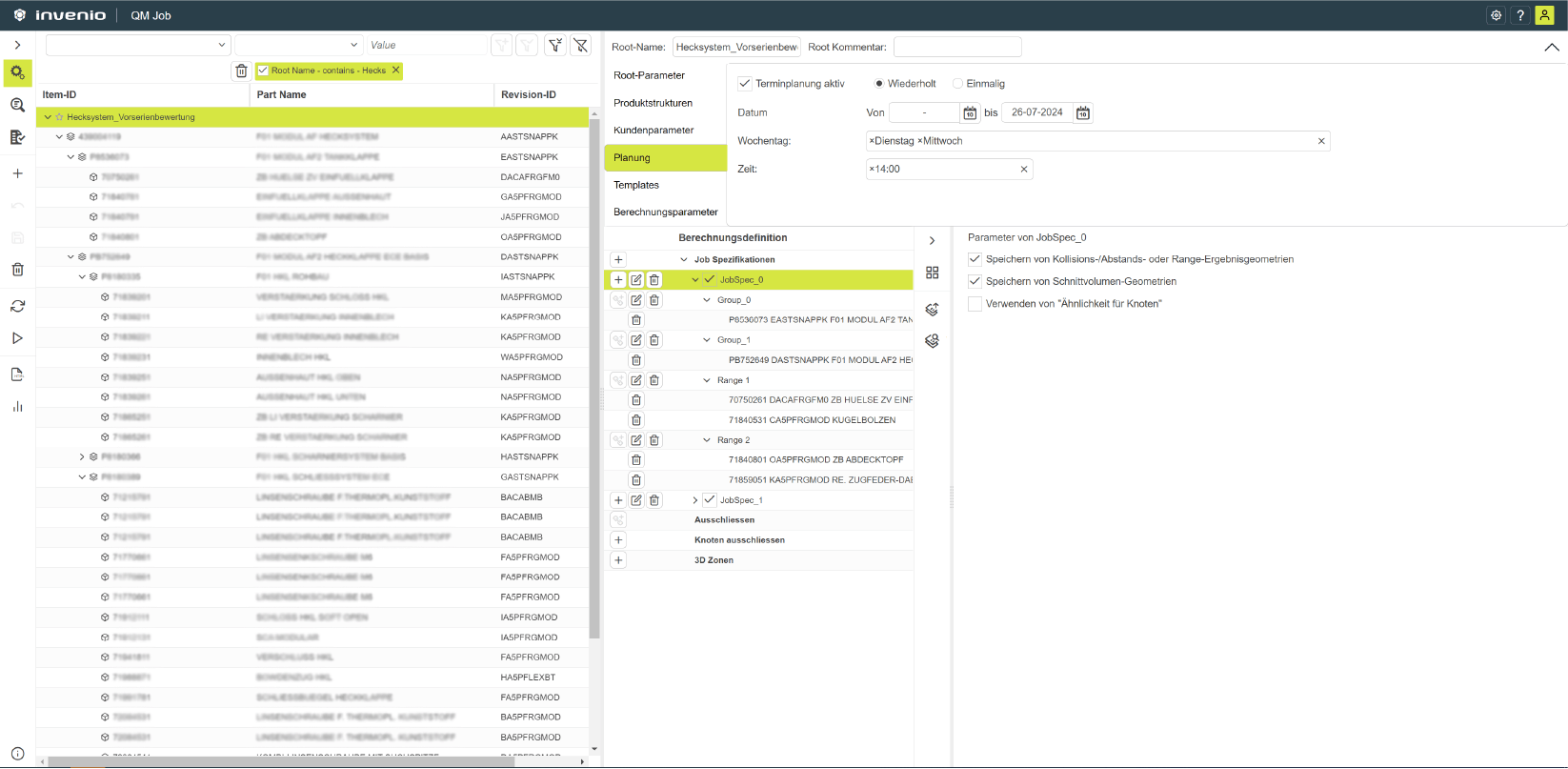

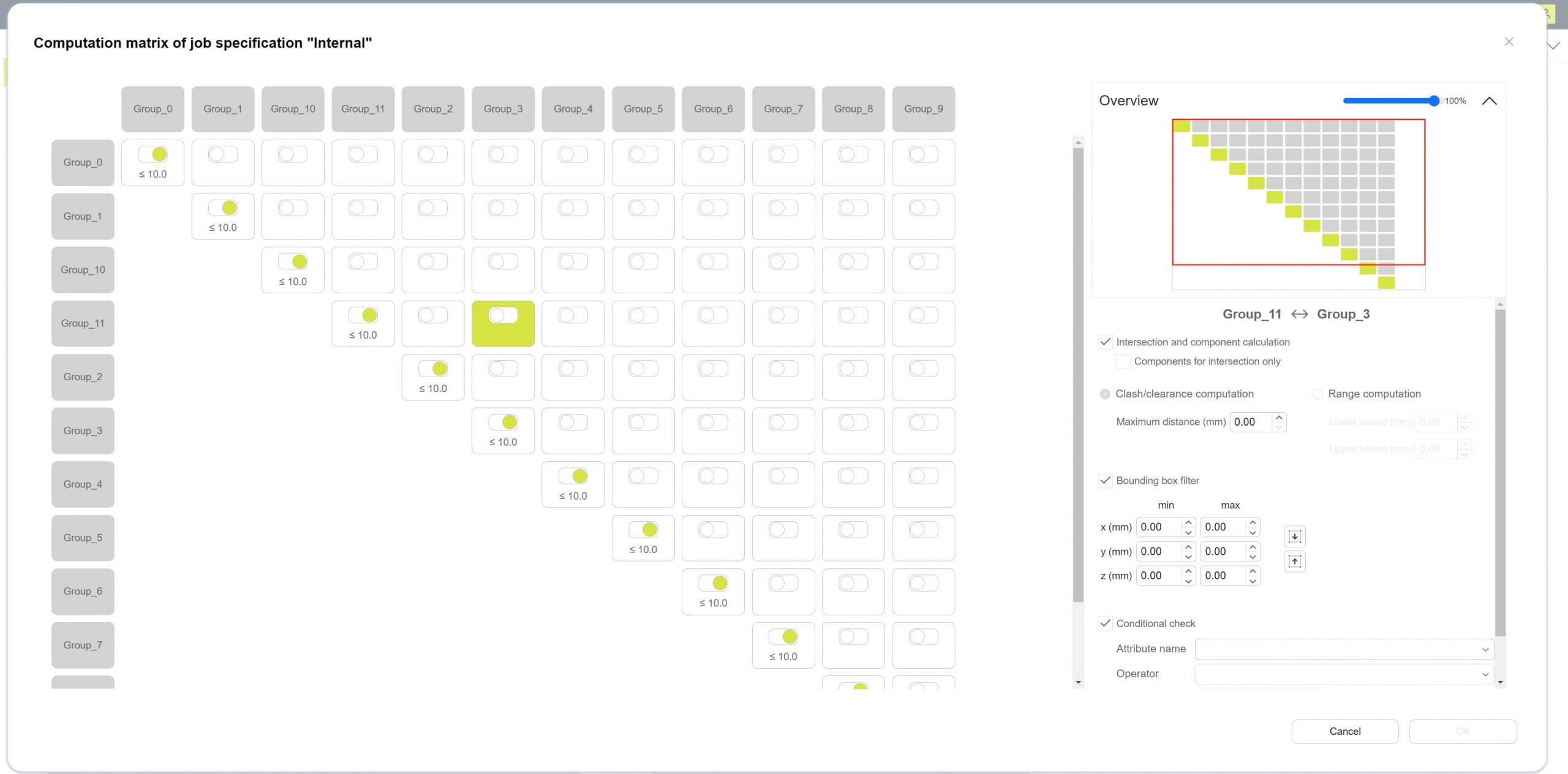

- Fully automatic calculation of all potential conflict points

- Intelligent job management with rule-based calculation

- Precise neighbourhood search identifies potential problem pairings

- Intelligent inheritance logic only presents what is new or has been changed

- Similar relations are available at the touch of a button

- Simple processing of big data with low hardware requirements

Artificial Intelligence

For an increase in efficiency of up to 80% compared to manual assessment:

- AI is already in productive use and assists the user

- Calculation of additional information for AI in the background

- Fully automatic image generation for the preparation of potential conflict areas

- Independent assessment of problem areas depending on the selected confidence level

- Unique training process – the learning AI looks over the user's shoulder and thus becomes increasingly intelligent and efficient

Virtual Geometric Validation –

Industry-Independent and Accessible for all Product Developers

The Choice is Yours: Standard Product or Customised Solution

Quality-Monitor and Quality-Monitor Web are among our standard products that can be customised and integrated. Make no compromises and receive a customised solution for the entire process of virtual geometric validation, tailored to your needs.

Do you want to integrate the leading technology and intelligence for virtual geometric validation directly into your existing system with its own user interface? No problem. The unique modular structure of Quality-Monitor and Quality-Monitor Web makes this possible. The individual technology modules can be flexibly combined and integrated.

You have a wide range of options via the REST API: You can use Quality-Monitor Web either as a standard application, a customised solution or a client you have developed yourself. Quality Monitor Web can also be installed, rolled out and managed centrally, both on-premise and in the cloud.

We will be happy to advise and inform you.

Advantages of Virtual Geometric Protection

Virtual geometric validation with Quality Monitor and Quality Monitor Web leads to a significant increase in efficiency in digital product development. Thanks to the automated processes and support from artificial intelligence, developers can identify and resolve potential problems faster and more precisely. This significantly reduces development time and enables shorter development cycles.

Another key advantage is the drastic reduction in manual assessment work. The AI-controlled evaluation and automatic image generation allow developers to focus on the most important problem areas without having to carry out time-consuming manual checks. This leads to a significant reduction in the workload of development teams.

The integration of AI and powerful algorithms in Quality-Monitor and Quality-Monitor Web ensures high accuracy and reliability of the inspection results. The automated calculations and intelligent evaluation methods minimise the risk of errors and ensure consistent inspection quality.

The efficient utilisation of resources is another advantage of virtual geometric validation. By reducing manual effort and optimising inspection processes, companies can achieve considerable cost savings. In addition, the low hardware requirements of Quality-Monitor and Quality-Monitor Web enable cost-effective implementation and maintenance of the software.

Quality-Monitor und Quality-Monitor Web erleichtern die Kommunikation und Nachverfolgung von Problempunkten durch automatische Reports und Statistiken. Die tagesaktuelle Übersicht zu allen Konfliktstellen und die Historie jedes Problempunkts sorgen für eine eine transparente und nachvollziehbare Dokumentation des gesamten Prüfprozesses. Dies verbessert die Zusammenarbeit innerhalb der Teams und mit externen Partnern.

Future Prospects and Further Development

Virtual geometric validation does not stand still. As technologies and methods continue to develop, there are always new approaches and improvements that make this process even more efficient and effective. One of the most promising developments is the further integration of artificial intelligence and machine learning. In future, these technologies will become even more precise and capable of solving more complex problems independently.

Another important development is the increasing use of cloud technologies. Quality Monitor and Quality Monitor Web are cloud-enabled and therefore already enable centralised installation and management. Cloud use is likely to increase further in the future, as it offers more flexible scalability and easier maintenance compared to on-premise solutions. This often enables companies to implement and operate the software more quickly and cost-effectively.

The flexibility and customisability of Quality-Monitor and Quality-Monitor Web make them an ideal solution for a wide range of applications. Thanks to the modular architecture and extensive customisation options, the solutions can be adapted to the specific requirements and processes of all companies. This applies not only to the automotive industry, but also to other sectors that can benefit from precise geometric validation. The REST API offers extensive integration options so that QM and QM Web can be seamlessly integrated into existing systems and workflows. This opens up new opportunities for companies of all sizes and industries to automate and optimise processes in product development as long as they work with 3D data.

While virtual geometric validation and geometry checking is already widely used in the automotive industry, among others, the technology still offers great potential in many sectors. In the aerospace, mechanical engineering and electronics industries, for example, there are similar requirements for the precise geometric validation of components, component groups and systems. The use of Quality-Monitor in these industries can lead to similar increases in efficiency and cost savings. Basically, Quality-Monitor creates transparency in the data wherever complex products are developed and large amounts of data come together.

Would You Like to Find out more about Quality-Monitor Web?

Would You Like to Find out more

about Quality-Monitor Web?

Michael Pretschuh will show you our solutions in dialogue and address your needs.

- Personal contact person

- live or via video call

- clarify all your questions directly