Due to an increasing number of variants and thus also of components or component groups, data volumes have continued to grow, just like the information in the 3D data. From the creation of the first 3D models to the development and marketing of the product in the virtual showroom, there are always challenges along the product life cycle when working with 3D data, interacting with it, visualising it or overcoming technical limitations.

When it came to 3D data reduction, companies were previously faced with a difficult decision: either the amount of data was reduced to a minimum, which resulted in a loss of surface quality, or the surface geometry was retained exactly, which resulted in a larger amount of data. Both approaches involved compromises that often proved to be a hindrance in practice.

Data Reduction for Engineering Applications

The VT-DMU modular software system from invenio Virtual Technologies revolutionises this approach. It enables data reduction of up to 90 per cent without compromising the quality of the surfaces. This combination of maximum reduction and the highest surface quality opens up numerous new application possibilities. With the VT-DMU modules for data reduction, the amount of 3D development data is reduced for various applications. All visible surfaces are retained and the interior is removed accordingly using an intelligent process. The wide range of functions can also perform structures, colouring, coarsening of the surface and much more to further reduce the amount of data. The results can be used for data exchange, for the visualisation of complete products or for confidentiality purposes, among other things.

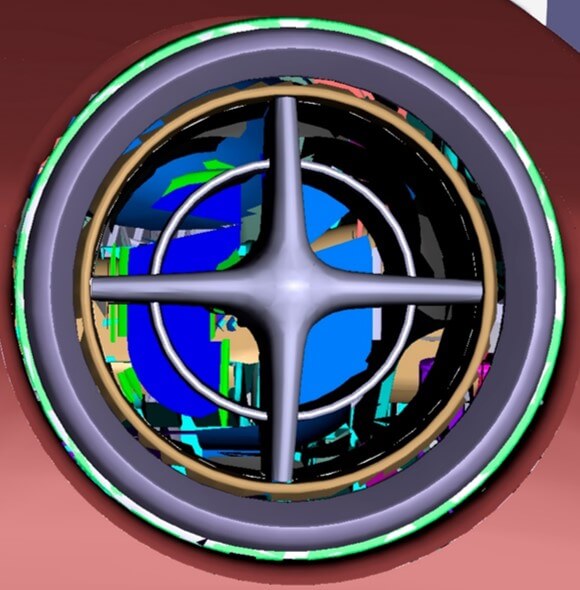

Engineering: Inside the shell, you can see some ‘geometry scraps’ that the algorithm was able to capture through the opening.

VR: All the geometries that humans can see can be seen inside. What humans cannot see is removed.

Special Requirements in VR Visualisation:

Visionary Approach through Orchestration of the VT-DMU Platform

The solution from invenio Virtual Technologies is based on an intelligent process and an innovative algorithm. As part of VT-DMU, it enables precise adaptation to the requirements of geometric complexity. Thanks to its many years of experience in the processing of geometric data, invenio Virtual Technologies has the necessary expertise to precisely analyse and optimise the behaviour of 3D data. Key parameters here are the manipulation and cleansing of the tessellated data and the decoring of the components.

For classic engineering applications, such as the simulation of an engine peak time, certain losses in surface quality are acceptable. Here it is important that the outer contours are fully visualised. However, this is not sufficient for VR visualisations. The smallest errors in the surface representation can impair the visual experience. The innovative VT algorithm ensures that the display limits depend solely on the quality of the output data and not on the amount of data.

Overcoming Technical Boundaries: an Example

An impressive example of the algorithm's performance is the data reduction of air vents within an instrument panel. Previous tools either displayed the louvres as ‘jagged’ or the reduction was so minimal that the amount of data became unacceptably large for applications such as VR glasses. With the VT solution, these problems are a thing of the past.

VT technology opens the door to numerous VR applications that were previously rarely utilised. The effects and influences of these new possibilities are manifold: daily VR conferences during product development, realistic training and further education, as well as fully automatically generated configurators and product presentations will become standard. With the right 3D database, this becomes reality.

VT-DMU: the Modular Solution for Digital Mock-Up (DMU)

For more than 25 years, invenio Virtual Technologies has been developing innovative solutions for Digital Mock-Up (DMU). The solution for data reduction is just one part of the modular VT-DMU software kit. Thanks to its many years of experience and in-depth understanding of geometry data processing, VT offers customised solutions for various applications.

Application Examples and Advantages of Data Reduction

- Data exchange: Smaller amounts of data can be exchanged more quickly. Maximising reduction is essential here.

- Confidentiality: Protection of intellectual property when exchanging data with suppliers. High-quality reduction is necessary to avoid loss of quality and protect internal geometries.

- High-end visualisation: For marketing purposes and customer experience, a small amount of data with maximum surface quality is crucial.

- Development tasks: Reduced data enables high-performance calculations, such as the simulation of an engine marriage.

- Real-time visualisation: The use of reduced data in real-time visualisations, such as in the browser or with VR glasses, requires maximum reduction with high surface quality.

The Importance of Intelligent Algorithms in Data Reduction

Automating data reduction saves time and effort. Intelligent algorithms know which data can be deleted to fulfil the various requirements. Recurring data reduction via an automated workflow ensures that the models remain up-to-date throughout development and can be exchanged efficiently.

The revolutionary 3D data reduction of invenio Virtual Technologies combines maximum data reduction with the highest surface quality. This enables new applications and improves existing processes, for example in product development or visualisation. Companies benefit from more efficient workflows and new possibilities offered by virtual technologies.

Would You Like to Find out More about Data Reduction?

Michael Pretschuh will show you our solutions in dialogue and address your needs.

- Personal contact person

- live or via video call

- clarify all your questions directly