Artificial intelligence (AI) is revolutionising product development and offers a wide range of opportunities for companies to make their processes more efficient and increase their competitiveness. This technological progress plays a decisive role for the future of Germany as an industrial centre by promoting innovation and opening up new market opportunities in international competition.

Importance and Advantages of AI in Product Development

AI systems can analyse large amounts of data in the shortest possible time and derive usable information from it. This is particularly relevant in digital product development, where complex 3D data and virtual models need to be constantly checked and optimised. By using AI, companies can, among other things:

- Increase process efficiency: AI makes it possible to automate time-consuming manual tasks, which speeds up product development and significantly increases efficiency.

- Improve transparency and accuracy: AI systems can analyse data more accurately and quickly, reducing the possibility of errors and improving the quality of products.

- Drive innovation: By utilising AI, companies can try out new methods and approaches in product development, resulting in more innovative and competitive products.

Practical Applications of AI in the Industry

Some concrete examples of the use of artificial intelligence in product development include:

Our Artifical Intelligence at a Glance:

Generic AI for Virtual Geometric Validation

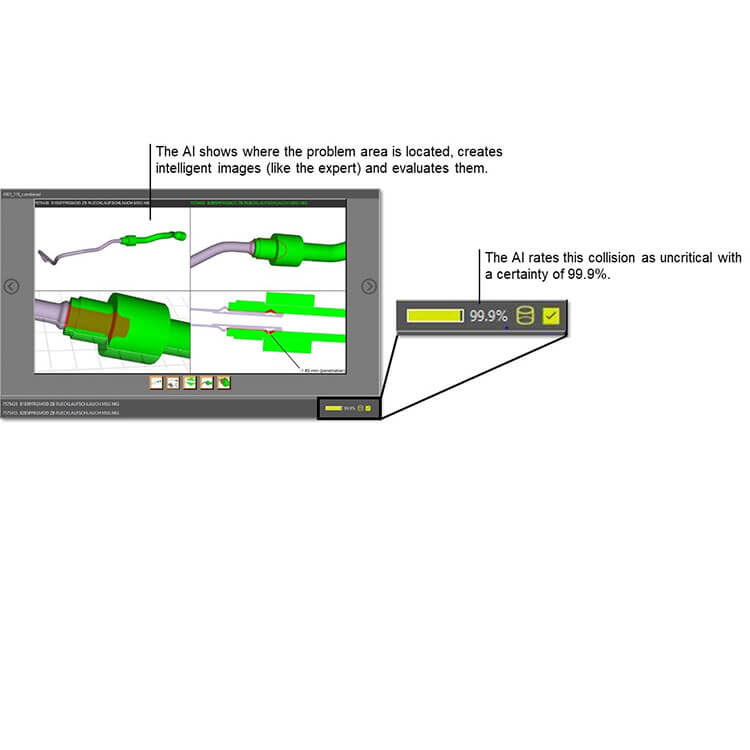

The AI is integrated into our standard product Quality Monitor (QM) and is already being used successfully in production. Many of our customers use QM to calculate several million component pairings for geometric consistency every day. The generic AI automatically prepares potential problem areas so that all relevant information is available at a glance and users can assess the conflicts quickly and efficiently. This significantly reduces manual effort. The AI can be used in a variety of ways, from preparing the data and enriching it with additional information to independently assessing the conflicts.

Advantages:

- integrated in the best-in-class product Quality Monitor

- already pre-trained by us and therefore immediately usable

- independent of customer data

- can be used across all sectors

- works hand in hand with users

- generates intelligent images and makes suggestions for conflict assessment

- has been in productive use since 2020

- increases efficiency in virtual geometric validation by up to 50%

Co-learning AI for Virtual Geometric Validation

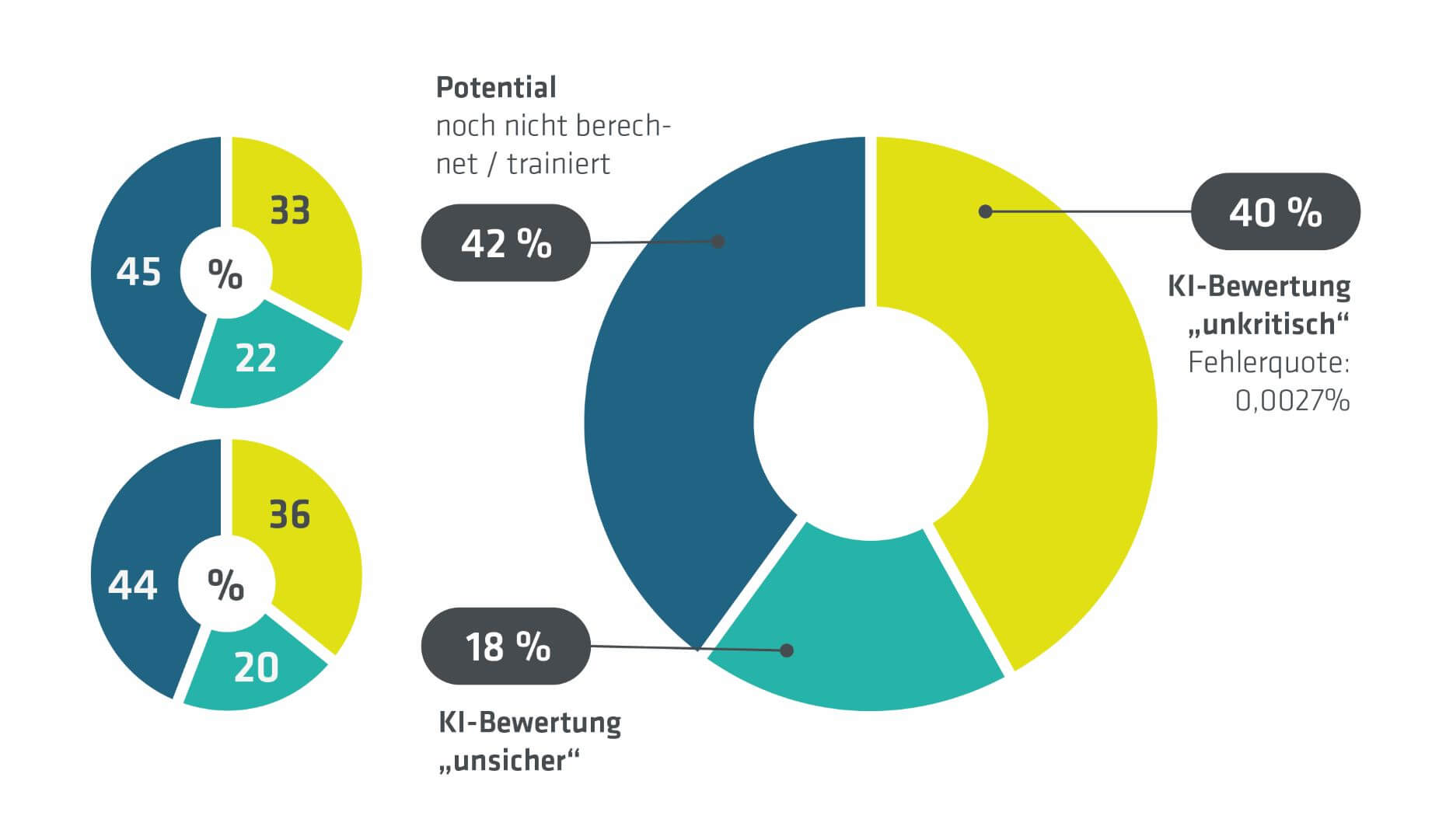

Our co-learning AI helps you to quickly and reliably assess conflict points in digital prototypes. It is integrated into the Quality Monitor, builds on the generic AI and adapts to specific requirements. The customised training is multi-track: the AI learns from both current and historical user evaluations and thus continuously increases its practical benefits.

For the training, we take various factors such as component relationships, metadata and the confidence level into account. This enables the AI to recognise that the same problem can be assessed differently depending on the context.

The co-learning AI always works together with the users, but - depending on the level of training and confidence - it can also make decisions independently and thus provide additional support. It creates evaluation suggestions for geometric conflicts by drawing on what it has already learned and analysing similarities.

Our vision is an automated and decentralised safeguarding of geometric data in product development. This significantly reduces the effort required for quality control. The integration of AI into OEM and PDM systems opens up new possibilities: Changes to CAD models can be automatically checked for conflicts. If the AI recognises a problem, it returns it directly to the developers - without any manual checking effort.

The combination of generic and co-learning AI forms the basis for the next technological leap and makes the development process more efficient and intelligent.

The AI continues to be trained and learns more and more. This allows its maximum potential to unfold.

Advantages at a glance

- in productive use for several years

- integrated in the best-in-class product Quality Monitor

- customised for your specific needs: adapts to your data, requirements and wishes

- is constantly evolving

- unique training process: looks over users' shoulders and thus becomes increasingly intelligent and efficient

- individual levels of confidence: can automatically evaluate conflict points independently

- recognises different assessments for the same problem

- if the AI learns incorrectly, the error can be retraced and removed afterwards

- increases efficiency in virtual geometric validation by up to 80%

AI Image Generation

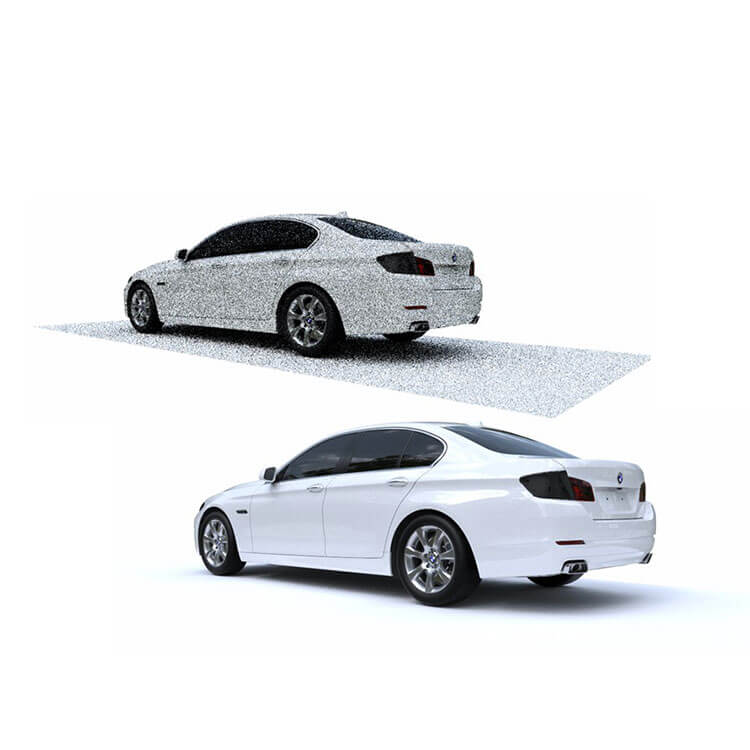

The AI for image generation is integrated in the VT-DMU module 'photo-inVT' and in the material editor. This means it can be easily integrated into customer processes and systems. The AI technology supports the rendering of images; the graphics are generated directly from the 3D data. AI is used by our customers to generate images from large amounts of data or to render 3D scenes in real time. The results can be used for marketing materials, photorealistic product presentations or the exact visualisation of product details and much more.

The VT solution guarantees perfect image quality with minimal calculation time and low hardware requirements. During the rendering process, the AI uses the trained mesh, optimises noisy image areas and finalises the image.

Advantages:

- integrated in the VT-DMU module 'photo-inVT' and in the software product Material-Editor

- easy integration into customer systems possible

- generates photorealistic images directly from 3D/CAD data

- calculates large amounts of data in a short time

- shorter calculation time: without AI 900 sec., with AI 45 sec.

- low hardware requirements

- automatic generation in batch

- no high costs for image creation by commissioning external agencies

AI Component Recognition

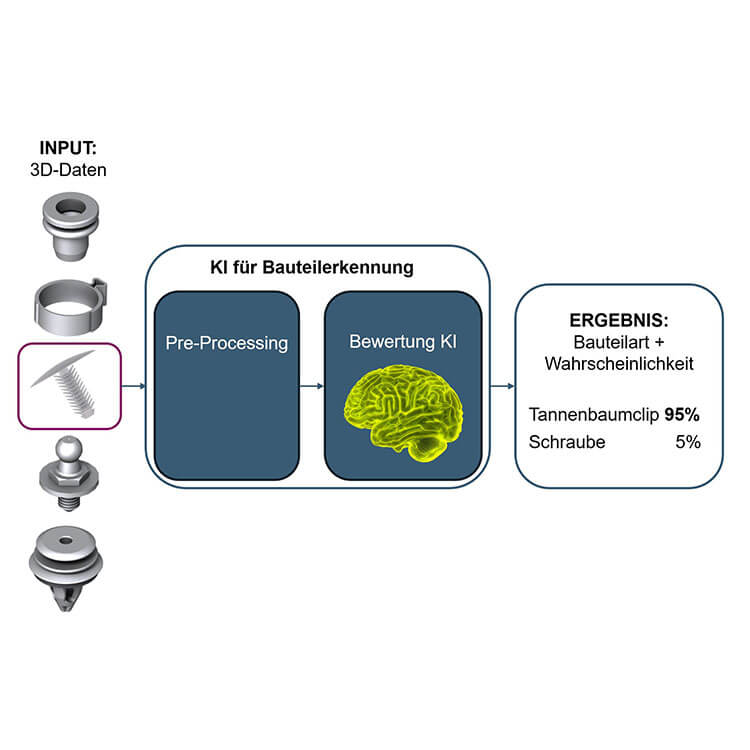

In addition to generic and co-learning AI, we are constantly looking for further use cases to successfully utilise artificial intelligence in virtual geometric validation. As part of a research project, we have successfully developed our AI for automatic component recognition.

The input is once again 3D data, which is recognised and classified by the trained neural network. The network can be adapted to customer-specific data. For large components, the AI uses other component properties so that components of any size can be recognised. The recognised component types are output with probabilities.

The AI provides valuable information that would not be available without it. These details can in turn be used in component handling systems, e.g. for targeted collision handling and calculation in virtual geometric validation, for production planning or for purchasing processes. The function is already integrated and available in Quality Monitor via 'Similar Relations'.

Advantages:

- integrated in the modular software toolkit VT-DMU

- is first fed with 3D geometries in order to learn

- then correctly identifies over 90% of small parts

- Indicates component type and probability

- Small parts could be included or excluded separately

- for larger components, in addition to the neural network, also uses other component properties

AI for Service

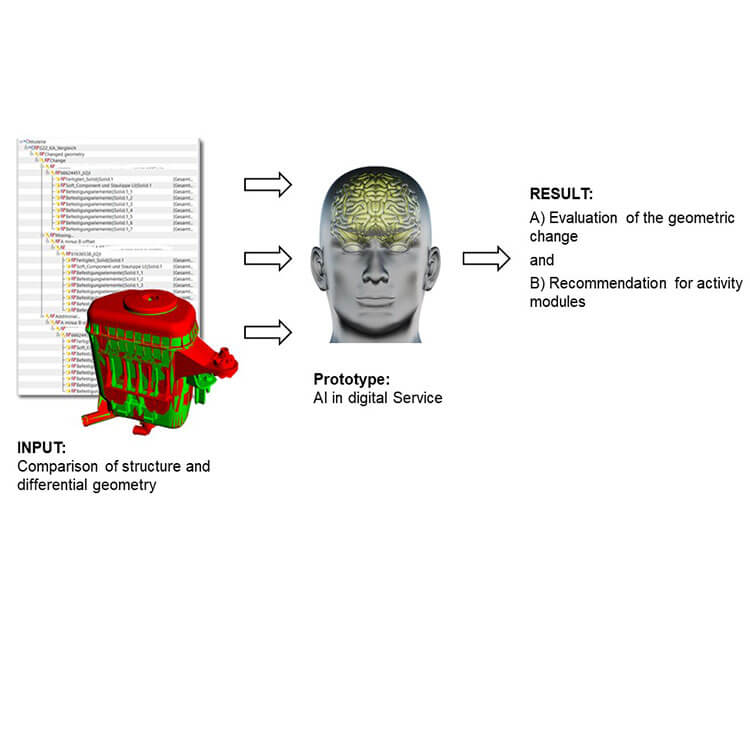

In digital service, service processes for a new product are simulated during development. Even before production begins, it must be clear how the result can be serviced or repaired. This means that all workshop information such as repair instructions, spare parts concepts or repair times must already be available at this stage.

More and more product variants are being developed under high time pressure. Physical prototypes, on which repair concepts could be developed, have been in decline for years. Due to these conditions, workshop information is increasingly being created completely digitally.

The mix of huge amounts of data, daily changes, high time pressure and many expert opinions is an ideal starting point for using artificial intelligence efficiently. Our "agents" automatically register every change in the development data. As soon as a geometric deviation is identified, it is presented to the AI prototype for evaluation. The AI immediately recognises what impact this deviation has on the repair concept and makes a recommendation as to whether the service process needs to be checked again. This process noticeably reduces the burden on users in their daily work, as they no longer have to look at every change in the data manually before making a decision.

Challenges and future prospects of AI in product development

The implementation of AI solutions in product development presents companies with challenges, such as the availability, transparency and quality of large amounts of data as well as the integration of AI into existing processes. Nevertheless, the advantages outweigh the disadvantages, especially when companies work with specialised AI providers that offer customised and scalable solutions.

For Germany as an industrial centre, this means that the increased use of AI will strengthen the competitiveness and innovative power of companies. This will help to position Germany as a leading location for technology and industry, secure jobs in the long term and counteract the shortage of skilled labour.

invenio Virtual Technologies: Your partner for AI in product development

Our artificial intelligence solutions make the difference and are unique on the market. We developed, trained and specialised our AI ourselves long before ChatGPT and the like. We already knew over ten years ago that big data and the associated data volumes could no longer be checked manually. In the meantime, we have proven many times that our intelligent technology offers real added value for many use cases in the DMU and 3D environment.

Our range currently comprises five products and is aimed at all companies that want to use cutting-edge technology to make their processes more efficient, their 3D data more transparent and their digital product development faster.

Our AI solutions are tried and tested and, just like our algorithms, can be integrated into the process. Our AI solution for Geocheck is integrated into the standard Quality Monitor product and can therefore be used by companies. For us, integrating software solutions is part of our day-to-day business. Thanks to our expertise in consulting, practical application and software technology, we can provide holistic support for the introduction of new DMU solutions.

AI Development at invenio Virtual Technologies

Our expertise for AI in practice

Lecture Bayern Innovativ: "ChatGPT is not a panacea."

Our Managing Director Hermann Gaigl took part in the online event on the topic of "Benefits and possible applications of ChatGPT for SMEs" with a specialist presentation. The event was part of Bayern Innovativ's transformation series. During the presentation, it was particularly important for us to emphasise once again that ChatGPT is not a panacea, especially not in the DMU environment for specific use cases in digital product development. This requires other, specialised AI solutions, for which the following always applies: you have to know your use case and your data precisely. How the users interact with the AI and how the AI is kept up-to-date must be clear from the outset.

Specialist lecture IHK committee meeting "The various facets of artificial intelligence"

At the invitation of the Chamber of Industry and Commerce for Munich and Upper Bavaria, our Head of Sales and Marketing, Michael Pretschuh, gave a presentation on the topic of AI at a committee meeting. It was primarily about our main focus on this topic, i.e. artificial intelligence in virtual product development. Or: "From the idea to development to productive use by customers"

For us, these steps are inextricably linked because we want to support our customers in their day-to-day business - a little more every day, a little better every day.

Symposium "Smart Products and Smart Systems": AI in product development - what we do and how we proceed

AI systems offer various forms of support in digital product development. At a symposium at the University of Kufstein, Hermann Gaigl spoke about why we developed our AI, what experiences we have had with customers and users during its introduction and what our findings are from ongoing productive operation.

The event showed us once again: whether in control engineering, CAE or art - everyone is confronted with the same problems, but the solutions with AI always depend on the use case and look very different.

Would you like to find out more about our Artifical Intelligence?

Would you like to find out more about

our Artifical Intelligence?

Michael Pretschuh will show you our solutions in dialogue and address your needs.

- personal contact person

- live or via video call

- clarify all your questions directly