Quality Monitor with AI makes the entire process of your virtual geometric validation faster, smarter and more reliable than ever before.

Experience the benchmark: Quality-Monitor with AI takes over your digital prototypes, processes huge amounts of data with high performance and delivers all potential conflict points. With the integrated AI, we raise the bar even higher - because it takes over the result evaluation.

Leading OEMs from the automotive and aerospace industries have been relying on Quality Monitor with AI for years. When will you join them?

This makes your process up to 80 % more efficient.

What sets us Apart

Fully Automatic Calculations

High-performance processing of all product structures and 3D geometries, even for extremely large data volumes

Intelligent Job Management

Automated, rule-based analysis for contacts, collisions, distance bands, free-flying components and much more.

Precise Neighbourhood Analysis

Automatically recognises all relevant pairings with conflict potential for maximum efficiency and safety

Intelligent Inheritance Logic

Automatically shows only new or changed conflicts, reduces manual effort and speeds up the workflow

Unique Similarity Check

Finds recurring and similar problem areas in the virtual prototypes and evaluates them at the touch of a button

Consistent User-Orientation

The user interface is intuitive and consistently adapted to real workflows

Maximum Transparency

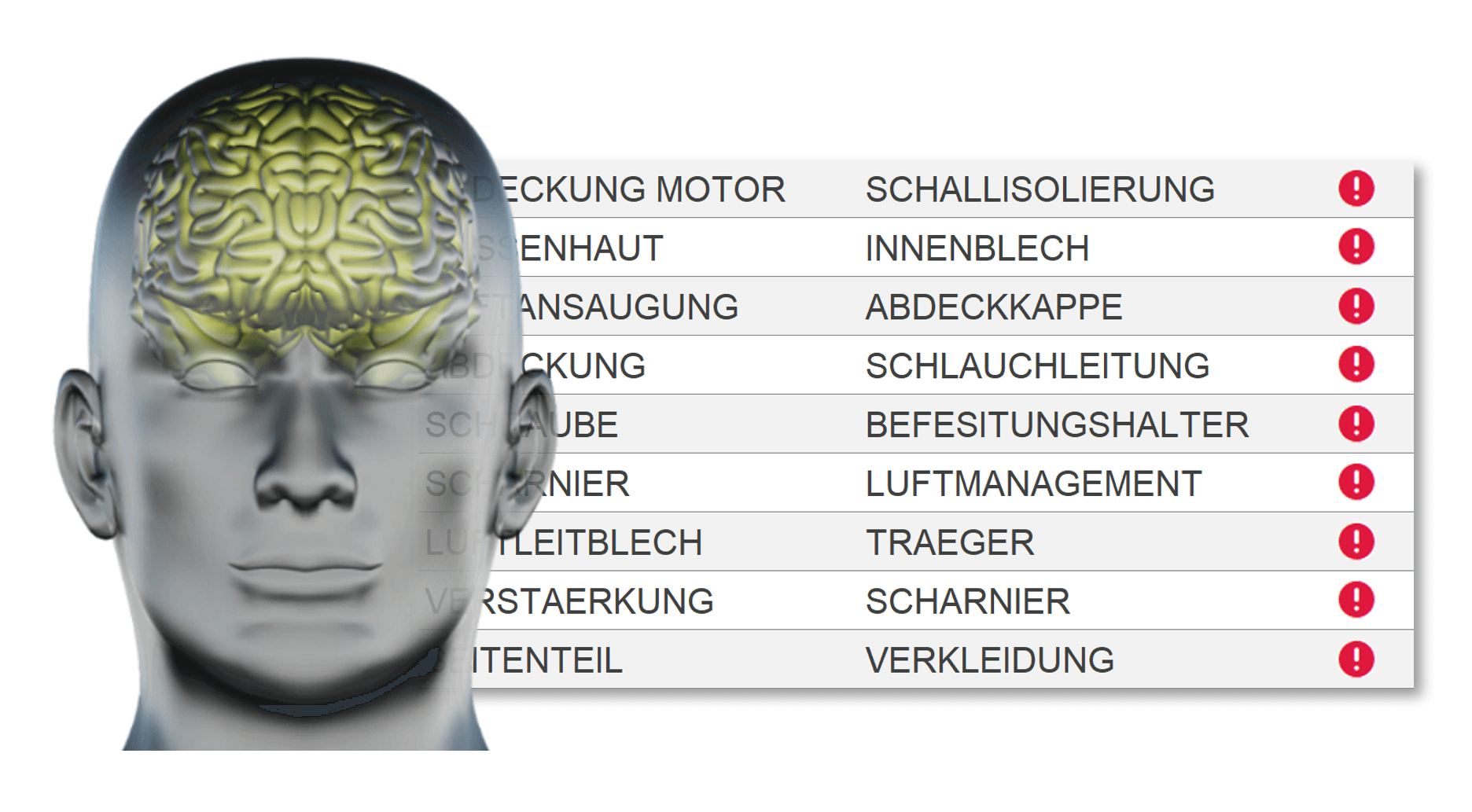

All relevant problem areas are clearly structured, updated on a daily basis and only show what really matters

Highest Efficiency for IT and Infrastructure

Modern web architecture with minimal requirements, quick installation and low maintenance effort

Artificial Intelligence

Our specialised high-performance AI thinks for itself, calculates ahead and translates complex results into clear decisions.

The best thing is that AI is constantly evolving. The more data the AI processes, the better it understands correlations, context and user behaviour - and thus becomes increasingly efficient. A unique form of support that our customers no longer want to do without after just a short time.

Generic AI

"Plug and Play"

The pre-trained AI can be used productively in all sectors immediately, regardless of customer data

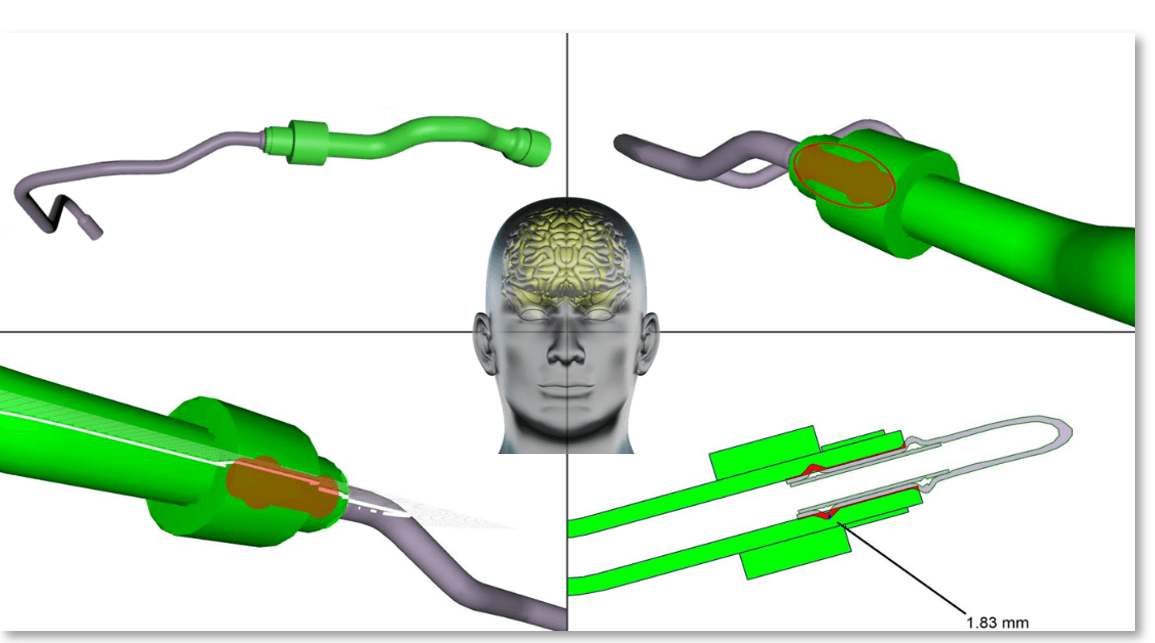

For a well-founded assessment, it generates intelligent images of each problem area and provides suggestions and information for efficient conflict assessment.

AI creates immediate benefits for all users in their day-to-day business.

The result: 50 % efficiency gain

Co-learning AI

"The AI learns individually from and with you"

The co-learning AI looks over the user's shoulder, continuously adapts individually to the 3D data provided and thus becomes ever smarter and more efficient.

The AI uses an adjustable confidence level to independently assess potential points of conflict and make decisions.

Once integrated into the process, the AI thinks for itself - it recognises points of conflict more quickly, simplifies complex processes and can completely take the pressure off.

The result: up to 80 % efficiency gain

Latest Features

Intelligent 3D Scenes

Each point of conflict is automatically provided as a 3D scene and specifically highlights the critical areas.

AI for Critical Relations

The AI now also evaluates critical conflicts and immediately provides all the information needed to quickly rectify errors. Find out more details here.

Optimised AI Images

The AI now provides images of inclusions and duplicate components. Thanks to optimised contour sharpness, even the finest details are visible.

Data Supply for AI

The service continuously generates all the additional information required to optimise the training quality of the AI.

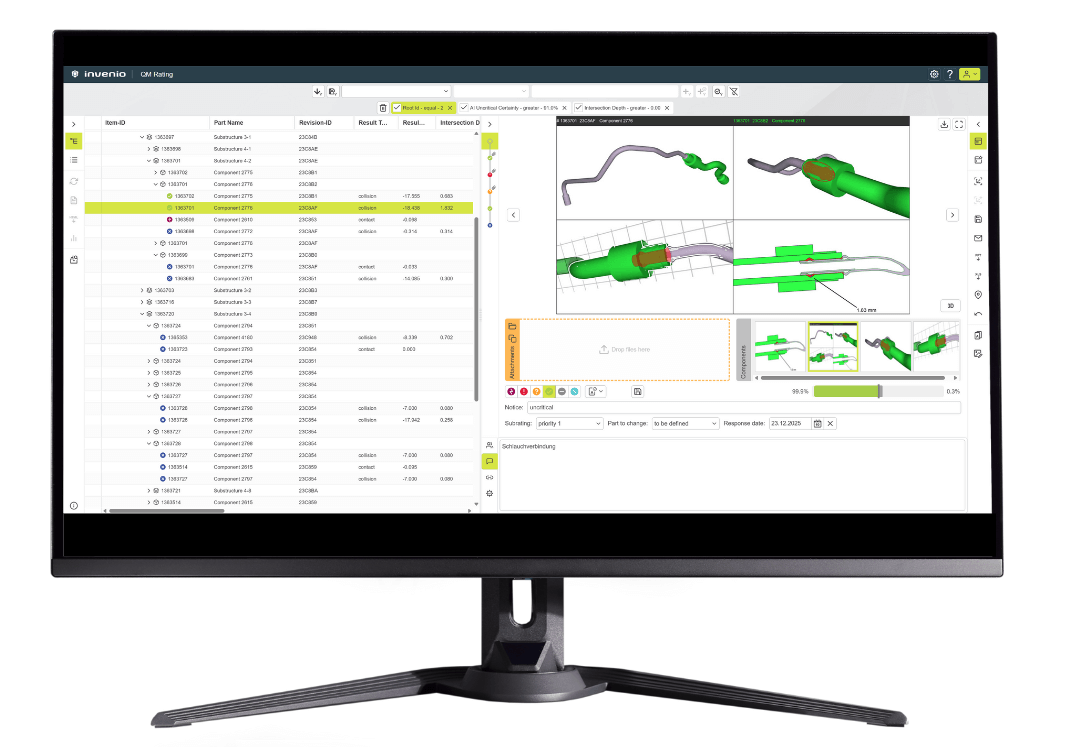

The GUI: Structured Presentation for Quick Access and Well-Founded Decisions

Quality-Monitor with AI – the benchmark for virtual geometric validation

With its AI-powered Quality-Monitor, invenio Virtual Technologies offers the leading solution for virtual geometric validation of digital prototypes. The software reliably identifies, evaluates, documents and communicates geometric conflicts such as collisions, clearance violations, free-flying components and more – fully automated and AI-supported.

The result: up to 80 percent efficiency gains in the process.

The integrated artificial intelligence takes the solution to a new level: it generates intelligent images, provides automatic 3D scenes and, with a configurable confidence level, enables informed, rapid decision-making and even independent evaluation. AI thus evolves from an assistance tool to a decision-making tool.

The REST API enables seamless integration into existing systems – whether as a ready-to-use standard product, individually customised or as a basis for your own applications. The modern web architecture ensures minimal IT requirements, fast implementation and low maintenance costs.

For large product manufacturers in the automotive, aerospace, mechanical engineering and commercial vehicle industries, the Quality-Monitor with AI creates maximum transparency in huge 3D data volumes, reduces manual effort and significantly increases the quality of assurance. Intelligent functions such as similarity checks, inheritance logic and precise neighbourhood analyses, as well as unique AI, make the software the global benchmark in virtual geometric validation.

Whether you are a medium-sized business or a large corporation, the Quality-Monitor with AI is the future-proof solution for companies that want to make their digital product development smarter, faster and more reliable.

Would you Like to Find out More about Quality Monitor with AI?

You would like to know More About

Experience Quality Monitor with AI?

Michael Pretschuh shows you Quality-Monitor AI and addresses your needs.

- personal contact person

- Live demo: on site or via video

- clarify your questions directly