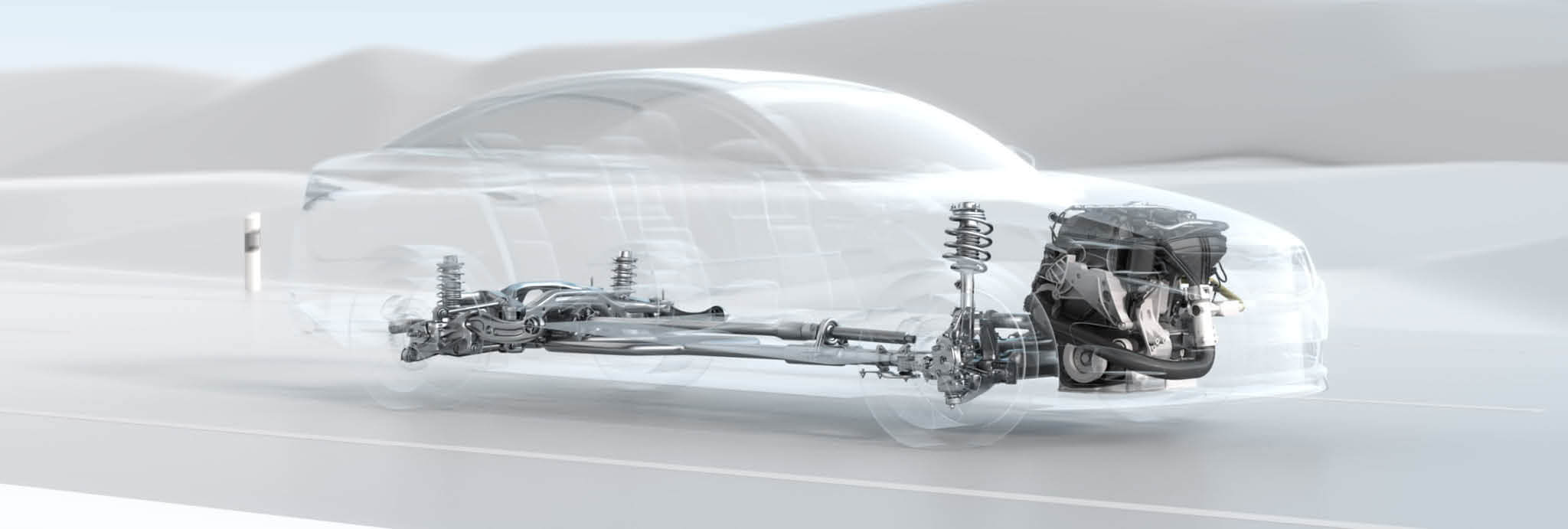

Holistic chassis development: concepts and production-orientated solutions for your vehicles

Nowadays, the demands placed on modern chassis are constantly increasing. Driving comfort, driving dynamics and precision are decisive factors that are immediately recognised by drivers and are important differentiating features for car manufacturers compared to the competition. In addition, energy efficiency and the adaptability of adaptive chassis systems to different road conditions are becoming increasingly important, while the safety and stability of driving behaviour in critical situations is becoming indispensable.

Intelligently developed components, assemblies and systems are needed to fulfil these diverse requirements. Our company has extensive experience in technical chassis development as well as comprehensive experience in the production of components of all kinds and has established efficient processes that enable us to realise these challenges in our projects successfully and unerringly.

Our Services in Chassis Development

- Geometric Integration

- Design

- Cable Laying

- FEM Calculation

- Prototyping and

small Series Production - Trial Planning/

Trial Support

-

Positioning and analysing chassis components in moving installation spaces

-

Automated installation space analyses in elastokinematically moving assemblies through coupling with multi-body simulation

-

Consideration of assembly and customer service requirements

-

Design suitable for load, production and installation space

-

Level of detail of the models depending on the status of the product development cycle and involvement of the system supplier and its production technology

-

Complementing the special component and manufacturing expertise of the system supplier with our chassis and complete vehicle expertise

-

Creation of design, enquiry and approval drawings and documents

-

Compliance with customer-specific standards for CAD data quality

-

Sheet metal, cast, forged, composite and plastic components

-

System design for air, vacuum, hydraulics and electrics

-

Cable routing for brakes, steering, air suspension, cooling systems

-

FEM structural mechanics linear and non-linear

-

NVH, eigenmodes

-

Crash simulation (accident/abuse)

-

Component optimisation in terms of structure, shape, material thickness and infiltration

-

Computational Fluid Dynamics (CFD) stationary and unsteady

-

Tolerance analyses on the influence on driving dynamics and costs

-

Service life analysis for damage location prediction

-

Plastic

-

Rapid prototyping

-

Plastic injection moulding

-

Fully milled parts

-

-

Metal

-

Fully milled parts

-

Rapid prototyping

-

Cast and forged parts as prototypes and series parts

-

Sheet metal parts

-

-

Determination and planning of vehicle requirements

-

Multiple use of test vehicles

-

Planning of test routes

-

Equipment of test vehicles

-

Logistics of vehicles and components

Through transparent communication between our project managers, we are in close contact with our customers in order to precisely understand and implement their technical and commercial requirements. In this way, we ensure that every solution not only complies with current standards, but is also one step ahead of its market competitors in a future-oriented manner. Put your trust in our expertise and let us develop innovative chassis solutions together!

Our expertise ranges from concept development and design to virtual and real-life testing. By using the latest technologies and our interdisciplinary team, we guarantee solutions that not only meet the highest quality standards, but also fulfil your specific requirements

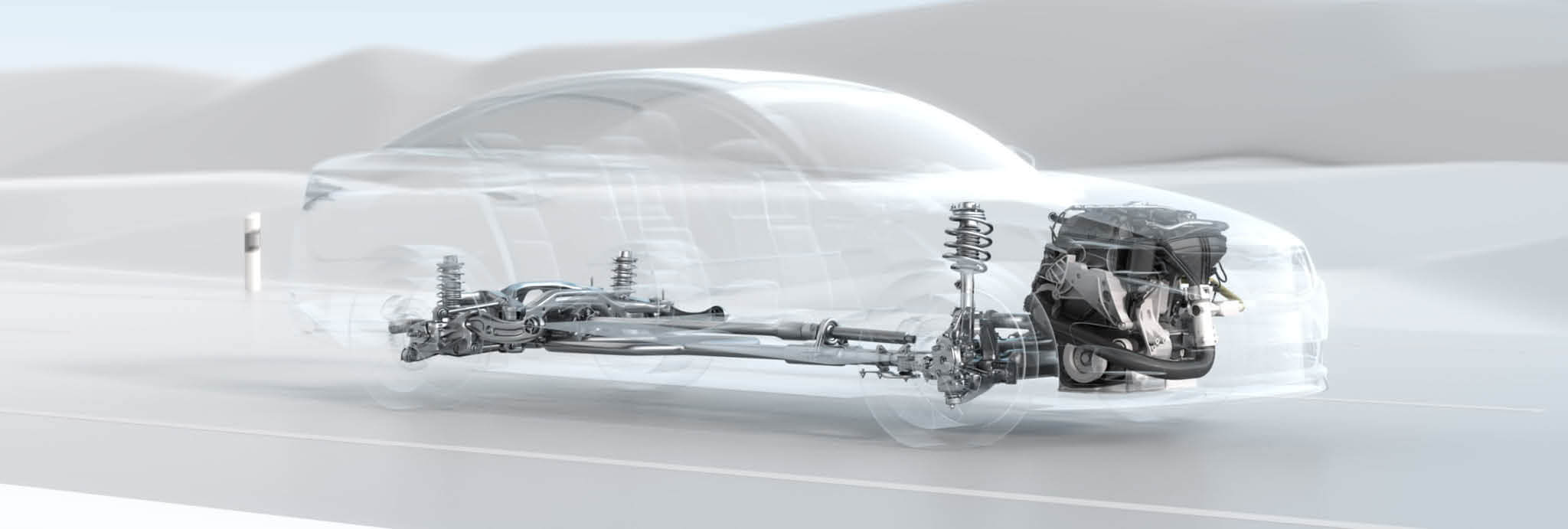

Axles

Spring/

Damper systems

Steering

Brake

Pedals

media and current-carrying lines

Wheels

Axles

- Axle carrier

- Handlebars

- Wheel carrier

- Axle powertrain

- Wheel bearing

- Thrust pad

Spring/damper

- Damper

- Spring seat

- Strut bearing

- Stabiliser bar

- Sway bar

- Damper cable

Steering

- Steering gear

- Steering gear housing

- Tie rods

- Steering column

Your success is our goal: convincing components and systems for your vehicles with our expertise in efficient development and production.

YOU WOULD LIKE TO CONTACT US?

We will be happy to answer any questions you may have!