As an engineering service provider, invenio offers the holistic development of high-voltage batteries suitable for series production for BEVs and PHEVs. The scope of services can be realised in support of an existing development team or as outsourced system development for partial scopes. If required, on-site support is also possible.

Our services include:

Benchmarking and conception

Installation space analyses

Production-

orientated

design

Tolerances and

Drawings

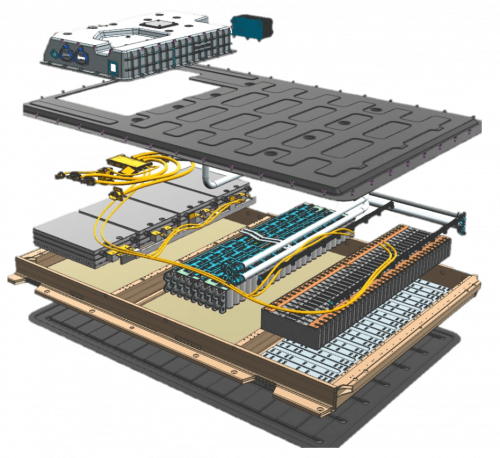

Simulation (FEM, Crush, Crash, CFD)

Optimisation (weight and costs)

Testing and supplier

support

Production of

Subcomponents

Concept development includes analysis, goal description, application of concept methods, and evaluation. Through internal production locations for component scopes and partnerships with numerous suppliers, our developers can offer production-oriented development, drawing creation and supplier support

From Individual Components to the Overall Development of High-Voltage Batteries

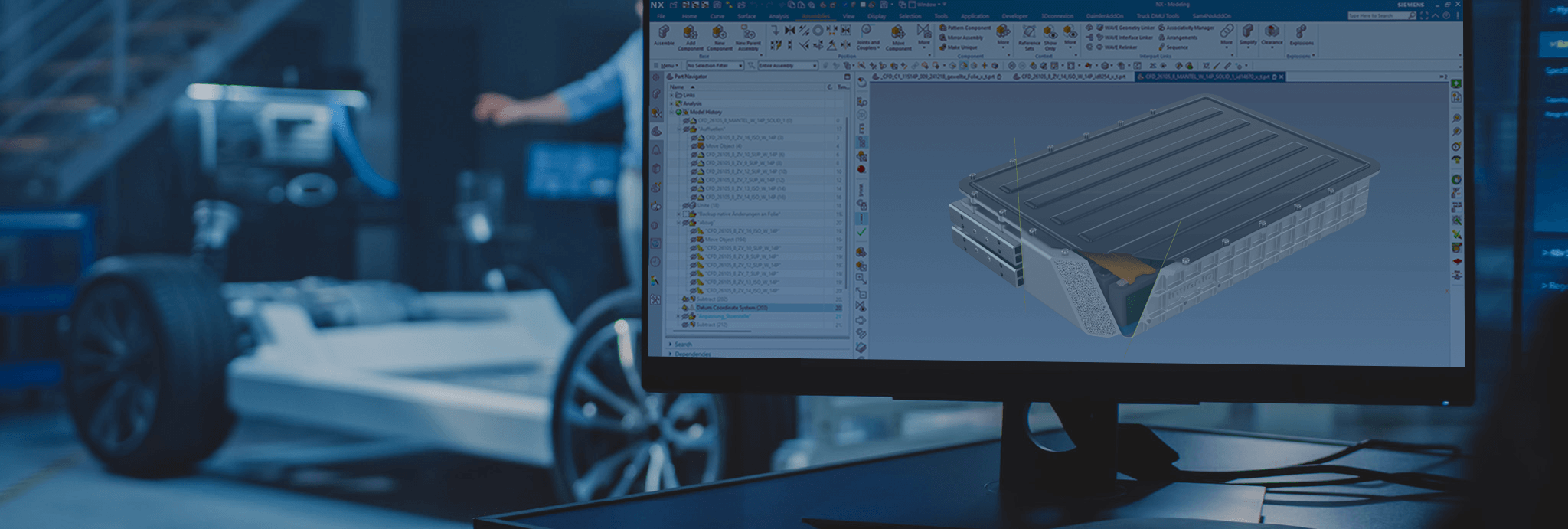

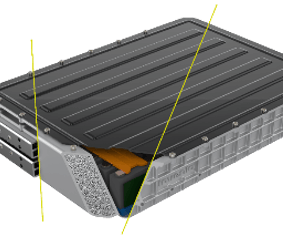

Our development scope includes the selection of the architecture and battery cell shape, their contacting and storage, as well as the connection of several modules - if modules still exist - and the control system to form an overall electrical system.

Depending on the concept, cooling plates or cooling lines can be integrated between the cells, modules or housings, or immersion cooling can be used for direct cooling. In a sealed housing, as a load-bearing or non-load-bearing structure of the vehicle, the energy storage system becomes a crash-relevant overall system.

We provide support in all development batches of high-voltage batteries up to series production and also with series production support.

Our expertise in the individual components:

- Cooling

- Housing

- Battery cell storage

and interconnection - Electrics / Electronics

- Sealing and Bursting

- Attachement and Crash

-

Cooling plates

-

Immersion cooling

- Cooling distribution

-

Contact

-

Expansion tank

-

Fastening

-

Special components with e.g. VDA or SAE coupling

-

Filling analyses and emptying

-

Volume determination and optimisation

Thermal simulation of a battery pack

-

Modular system for derivatives

-

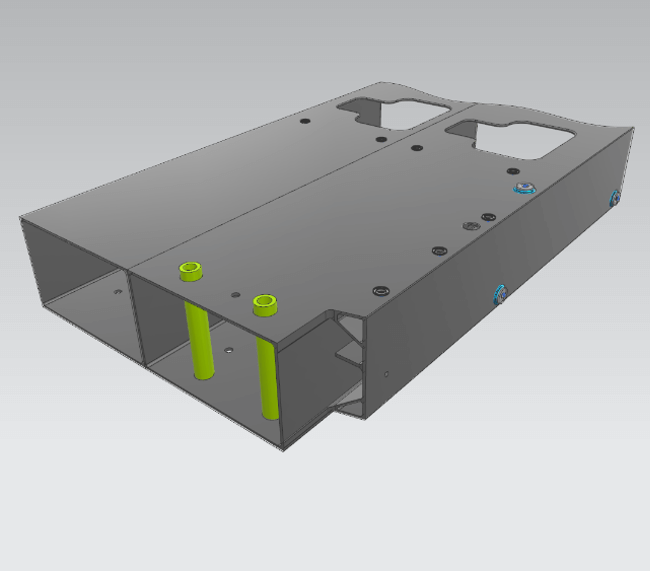

Cast, extruded and deep-drawn components

-

Integrated cooling

-

Optimised for Crash and Crush

-

Weight-optimised

-

Consideration of EMC specifications

-

Sealing concepts

-

Assembly sequences

Extrusion battery housing

-

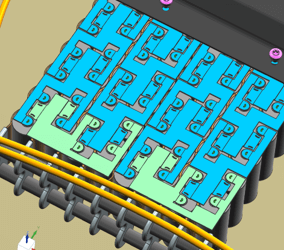

Cell contacting ZKS

-

Cell storage

-

Cooling the cells

-

Tolerance analysis

-

Assembly

-

Sealing

-

Bursting and venting

-

Creation of battery modules

- Cell-to-pack realisation

Round cell interconnection

-

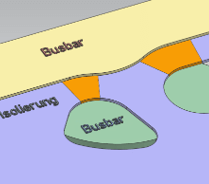

Busbars (bent, twisted)

-

Cooling

-

Contact protection according to IP

-

Relay, sensor and contactor arrangement

-

Tolerance calculation

-

Holder

-

Plastic housing

-

Cable sets

-

Connection plates for LV and HV plugs

- Clearance and creepage analysis

Clearance and creepage analysis in 3D

-

Rupture discs

-

Venting path

-

Sealing with solid and liquid seals

-

Design of O-rings

- Moulded seals

-

Measures for Crash and Crush

-

Holder made of sheet metal, cast iron and plastic

-

Weight optimisation

-

Holder for cooling, S-Box and cable sets

- Innovative approaches with aluminium foam, sandwich structures, etc.

- Simulation (static and dynamic)

Crash concept for HV energy storage

Manufacturing Process

Benefit from our independent opinion, concept development, evaluation, selection and constructive implementation of components. We can take over the preparation of enquiry documents, as well as the implementation of the enquiry and evaluation for decision documents and the coordination of suppliers.

Manufacturing processes and example scopes for traction batteries:

-

Aluminium extrusion presses for e.g. housings, modules and crash topics

-

Sheet metal forming and stamped parts for e.g. housings, cell contacting systems (ZKS), holders and busbars

-

Plastic injection moulded parts for e.g. cooling lines, insulation components, connectors, housings and holders

-

Machining for e.g. contact pins, cast parts and spacer sleeves

-

Plastic tubes for e.g. cooling lines

-

Welding for e.g. cell contacts, housings and spacer sleeves

-

Sealing with e.g. liquid seals, moulded seals or O-rings

-

Aluminium die casting, gravity die casting and sand casting for e.g. holders, housings, connector interfaces and crash topics

Your Added Value Thanks to invenio

Intelligent invenio software (VT-DMU) for checking derivatives, distances and assemblies

Short-term production of prototypes to secure your test set-up

Independent technically sound second opinion on one's own specialist are

Standard-compliant drawings and specifications for enquiries with suppliers

Further Services

YOU WOULD LIKE TO CONTACT US?

We will be happy to answer any questions you may have!