In the development of complex products, fast decision-making and the optimal utilisation of existing installation spaces play a decisive role - especially when the framework conditions change. A new function of invenio Virtual Technologies provides practical and targeted support.

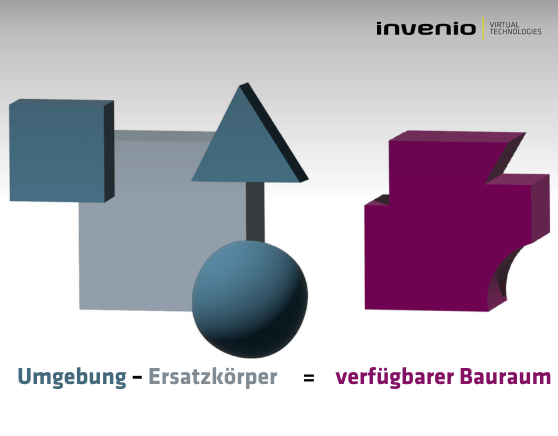

Geometry subtraction can be used to automatically process replacement bodies for free installation spaces in digital prototypes. This gives users a precise overview of which areas within a complex assembly are still unused. The resulting geometries enable visual evaluation, allowing users to recognise potential installation space conflicts at an early stage and place new components efficiently. This function adds another innovative component to the VT-DMU modular software system.

Increasing Demand for Free Space in Products

The reason for the increasing importance of installation space analyses is that modern, complex products contain more and more components - such as control units, sensors or containers - while the available space on common development platforms is becoming increasingly scarce. In particular, the parallel development of e-mobility and conventional drives on an identical vehicle basis is intensifying competition for free installation space. At the same time, the trend towards autonomous driving is creating additional requirements: New functions and safety standards require extensions such as additional cameras, LIDAR systems and powerful control units.

Precise installation space analysis using geometry subtraction is therefore essential in order to show in the digital prototype which areas can actually be used for additional components. This is the only way to avoid conflicts and efficiently control development costs.

The use case from practice provides an illustrative example: a geometry is created at an OEM customer's request that maps the available installation space in principle as a 3D replacement body. Geometry subtraction is then used to subtract the surrounding dynamic component perimeters, whose movement spaces must be kept free. This creates a precise image of the actually usable installation space, which also serves as the basis for subsequent design decisions and the definition of the required design limits.

Result Geometries as a Transparent Basis for Subsequent Processes

The result of the analysis is a generated geometry that clearly represents the determined free spaces and can be used directly for downstream design or installation space or package work. With geometry subtraction, invenio Virtual Technologies is once again setting new standards for a specific use case: the function makes the decision on the placement of new components faster, more precise and completely digital. For companies, this creates a transparent, highly efficient development environment that ensures an innovative edge.

Contact:

Michael Pretschuh

invenio Virtual Technologies GmbH

michael.pretschuh@invenio.net

M: +49 (174) 3052212